With the development of Industry 4.0, industrial robots are widely used in various industries such as automobiles, machinery, food, and logistics. Industrial robots are more valuable than you might think. The more industries use industrial robots, the more those industries need people who can operate these robots. Due to the rapid innovation of industrial robots, there is a great demand for vocational training equipment.

Industrial robot-related majors include industrial robot technology, application and maintenance, and mechatronics technology. In addition to the majors directly related to industrial robots, other majors also require robotics training equipment in professional courses, such as machine manufacturing and automation. Therefore, robotics training equipment has wide applications and a broad market prospect.

There are many types of robotics training equipment, many of which have different performance and application ranges, and it is difficult to find suitable equipment. So, how do we choose the robotics training equipment that suits us?

This article lists the 8 best Dolang industrial robotics training equipment in 2022 to help you decide what kind of equipment is best for you.

#1 DLDS-1190 Industrial Robot System Integration Training System

DLDS-1190 adopts FANUC and Siemens parts. Operational assessment, intelligent transfer-sorting-palletizing, gift wrapping, process application welding, numeric keypad assembly tasks, etc., can be completed on this device.

Equipment parameters: length*width*height=4m*3m*2.5m (the width can be adjusted)

Ranges of application: mechatronics engineering, industrial robot major.

DLDS-1190 can train students to master the operation, debugging, visualization application, PLC principle and programming, sensor technology, and Profinet industrial Ethernet communication technology of industrial robots.

The DLDS-1190 is a full-featured robotics training equipment with various training items, which is very popular. Due to its excellent performance, it has become competition equipment for world-class vocational skills competitions. The players have achieved good results using this robotics training equipment.

3 reasons for recommendation:

- The equipment’s width can be adjusted as needed, and the application is very flexible.

- The parts are purchased from the world’s most advanced manufacturers with excellent quality.

- The equipment is a vocational skill competition equipment, which can train a variety of competition items.

#2 DLDS-3717 industrial robot technology application system for skill competition of industrial robot

DLDS-3717 consists of a touch screen, a six-axis robot, and a four-axis robot. It can complete product transmission, identification, assembly, detection, and storage tasks.

Equipment parameters: The robotics training equipment consists of 7 modules. The corresponding modules can be placed on the training platform when training different tasks.

Ranges of application: TVET schools.

The vocational training equipment can train students to master 26 training items, including robot and PLC communication, PLC application, six-axis robot training and calibration, four-axis robot training and calibration, and application of visual human-machine interface.

DLDS-3717 has various training items and easy-to-replace modules, which are convenient for training different tasks. In actual teaching, it is easy to disassemble for easy placement.

3 reasons for recommendation:

- The equipment has many training modules and is easy to replace.

- The equipment can train 26 items, train students in various aspects, and facilitate teaching.

- The equipment is installed with a six-axis and four-axis robot, which is very advanced.

#3 DLFA-JXS four-joint robot training system

DLFA-JXS is developed to integrate robot teaching, R&D, and learning. The robotics training equipment consists of an aluminum alloy training platform, a Mitsubishi robot, a PLC controller, electrical and pneumatic devices, etc.

Features:

This device is very flexible to install, and the robotic arm can be installed on a desktop, base, or linear sliding base as needed. In addition, the device is small in size, easy to transport, and can be purchased in large quantities.

Ranges of application: industrial robot major.

Using the device, students can gain knowledge of robotic mechanical parts, practice pneumatic connections, practice circuit connections and troubleshooting, and more.

3 reasons for recommendation:

- The equipment is small and occupies a small area, which is easy to install and suitable for large-scale purchases.

- There are various installation methods for the robotic arm, which can be installed freely according to needs.

- The training items are targeted and can improve teaching efficiency.

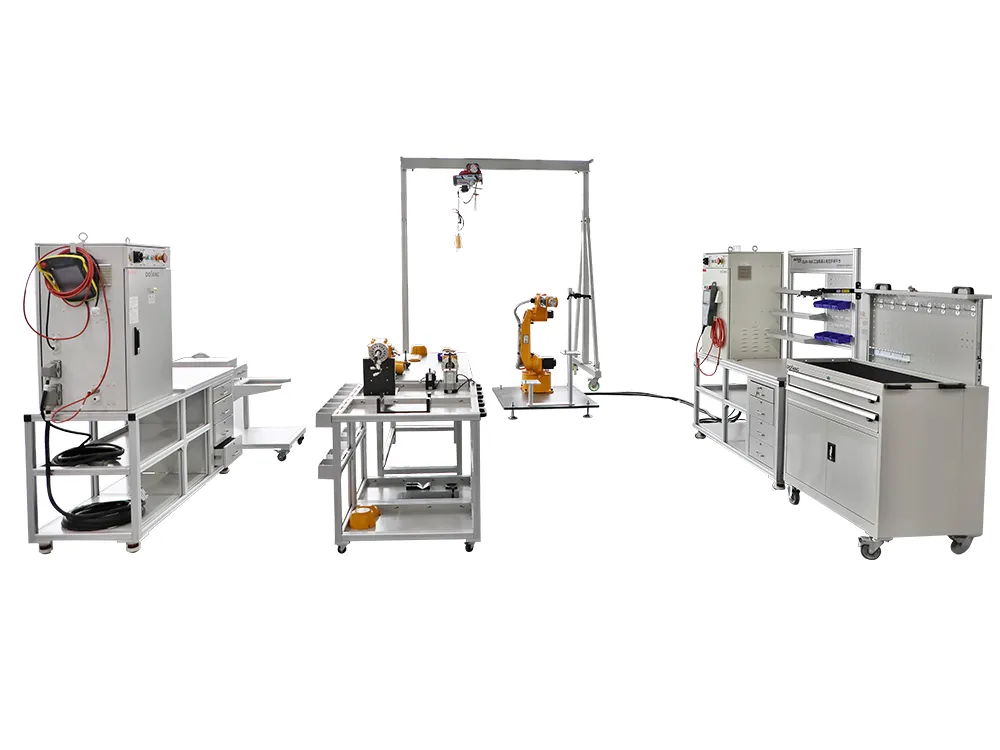

#4 DLIR-106 industrial robot assembly&disassembly, operation&maintenance workstation

DLIR-106 is a large integrated workstation. It can complete 27 training items, such as industrial robots’ installation and parameter setting.

Features:

The equipment training program is comprehensive and integrated, so the robotics training equipment contains various machinery and covers a large area suitable for systematic teaching. The device supports systematic instruction and helps students acquire systematic knowledge.

The equipment involves more machinery, so it has higher requirements on the application site. The equipment needs to be used in an environment with no dust, no oil fume, dry, no flammable objects, and no corrosive liquids and gases to ensure the safety of the equipment and protect equipment.

Ranges of application: industrial robots, robotics, and other majors

This robotics training equipment contains a variety of machinery and is a large workbench integrating disassembly, operation, and maintenance, which can be used for examination.

3 reasons for recommendation:

- The equipment is a large workbench containing various devices, which is conducive to systematic teaching.

- The device uses good components that can perform complex tasks.

- The equipment can carry out 27 training items and be used as examination equipment.

#5 DLIR-116 industrial robot operation and programming application system

DLIR-116 is a device for industrial robot system operation and maintenance personnel. It consists of three parts: a training platform, a computer table, and a module placement rack. DLIR-116 can meet the needs of technical personnel to learn. If you need it, we provide personalized customization as well. For example, suppose you don’t think a computer desk is necessary. In that case, you can buy it locally and just buy the operating equipment.

Features:

The operating table of the application system is equipped with pulleys, so it is very convenient to place and transfer positions. And the device is equipped with brakes, so its stability is good, don’t worry if the device will shift.

Ranges of application: industrial robots, industrial robot technology, and other majors

This robotics training equipment provides industrial robot technicians with 10 training items, including industrial robot operation, debugging, programming, and fault diagnosis. Compared with other training equipment, this equipment training program is more professional and advanced.

3 reasons for recommendation:

- The equipment is mainly for professional technicians in the field of industrial robots, and the training items are more accurate and professional.

- The device supports customization.

- The device is practical and easy to place or change position.

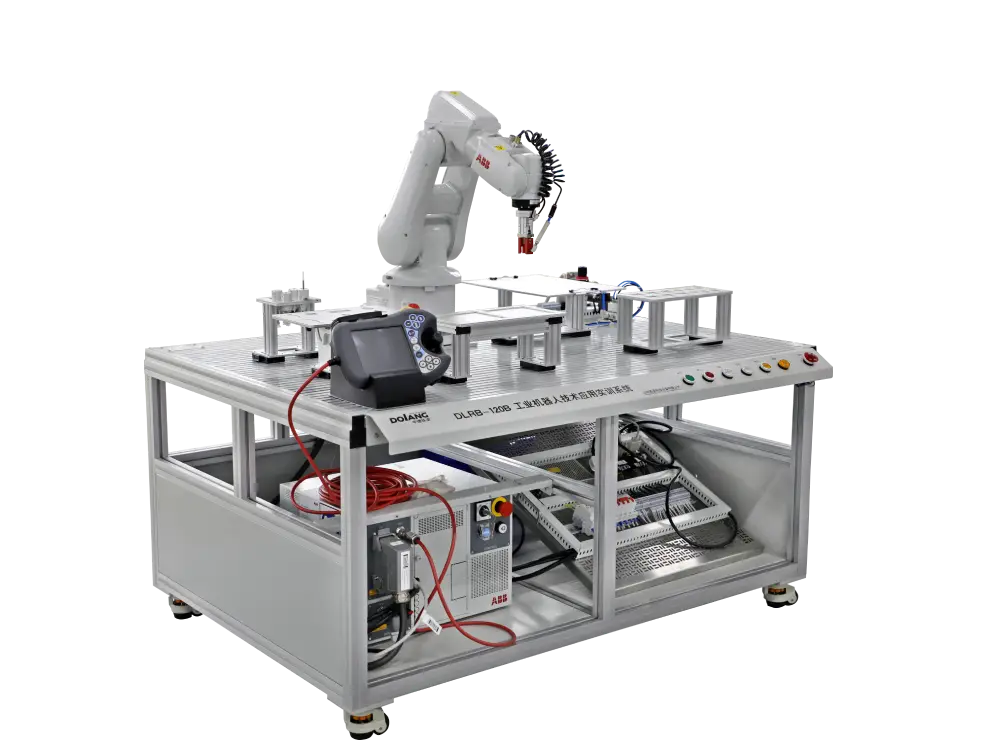

#6 DLRB-120 industry robot basic application control training system

DLRB-120 is suitable for ABB robots, Fanuc robots, Kuka robots, Mistubishi robots, and Efort robots. So the device can be customized according to your needs.

Features:

The equipment supports a variety of operations, and different tasks can be performed by changing modules, such as puzzle drawing, handling, and palletizing.

Ranges of application: industrial robot major

The robotics training equipment can perform 17 training items, such as installation and wiring of the industrial robot controller, industrial robot initialization and parameter recovery, and various training items. Because the equipment supports 6 major brands of robots and can be customized, customers deeply love it. It has become one of the most popular robot training equipment in Dolang.

3 reasons for recommendation:

- A variety of robots are applicable and can be customized.

- The equipment is specially designed for robot training and has specialization characteristics.

- The equipment is mature in technology and provides a high-quality platform for teachers and students to learn.

#7 DLRB-341M modular industrial robot open training system

DLRB-341M is technical training equipment designed for industrial robot technicians. It is mainly intended for robot technicians and can also be used for teaching. The robotics training kit consists of a robotics training platform and a module placement rack. This robotics training equipment integrates various technologies such as pneumatic control, PLC control and networking, mechanical technology, industrial robot programming, and application technology. It is a multi-functional and integrated device.

Features:

The robot of this device is a six-axis robot, which has more training items than the four-axis robot.

Ranges of application: technical training for robotic technicians, teaching in vocational schools

The equipment consists of a six-axis robot, a basic installation platform, a fixture library module, a basic application module group, a process expansion module group, a pneumatic system, an electronic control system, and a module placement rack. DLRB-341M can train nearly 30 projects in five directions: basic aerodynamics experiment, basic circuit experiment, mechanical structure and integrated wiring training, PLC control technology experiment, basic operation and programming of industrial robots. The training program is precise, specially designed for robotic technicians, and can also be used for school teachers and students to learn.

3 reasons for recommendation:

- The device is designed for robotic technician training, suitable for technicians to improve themselves.

- The device can perform 30 training tasks, which are numerous but precise.

- The device can be customized according to your needs.

#8 DLRB-934 modular industrial robot open training system

DLRB-934 robotics training equipment adopts computer simulation technology to simulate tasks such as assembly, gluing, tire stacking, and alignment inspection. The operating table is made of high-quality steel, and the surface is sprayed, which is strong and durable. The material of the control panel is a good PVC film. Pulleys are installed at the bottom of the device for easy movement.

Features:

Pulleys are installed at the bottom of the device, which is convenient for placement and movement.

Ranges of application: industrial robot major

DLRB-934 can train 19 industrial robot projects. Through simulation technology, students can operate machines, understand the production process of modern industry, and improve their practical operation ability in addition to learning theoretical knowledge.

3 reasons for recommendation:

- The equipment is made of high-quality raw materials and is durable.

- The device is easy to move and will not deviate easily after placement.

- The equipment can train 19 items, multi-function.

The above 8 robotics training equipment is popular because of their high quality and complete functions and because we will provide teaching aids to customers who purchase the devices.

Customers who purchase these devices will enjoy permanent technical support provided by our company. We will also provide you with the APP to simulate operating and disassembling machines in teaching. If you have any questions in use, you can contact us, and we will arrange for technicians to deal with your problems.

Hope this article will help you choose robotics training equipment. Welcome to inquire!