1.Overview

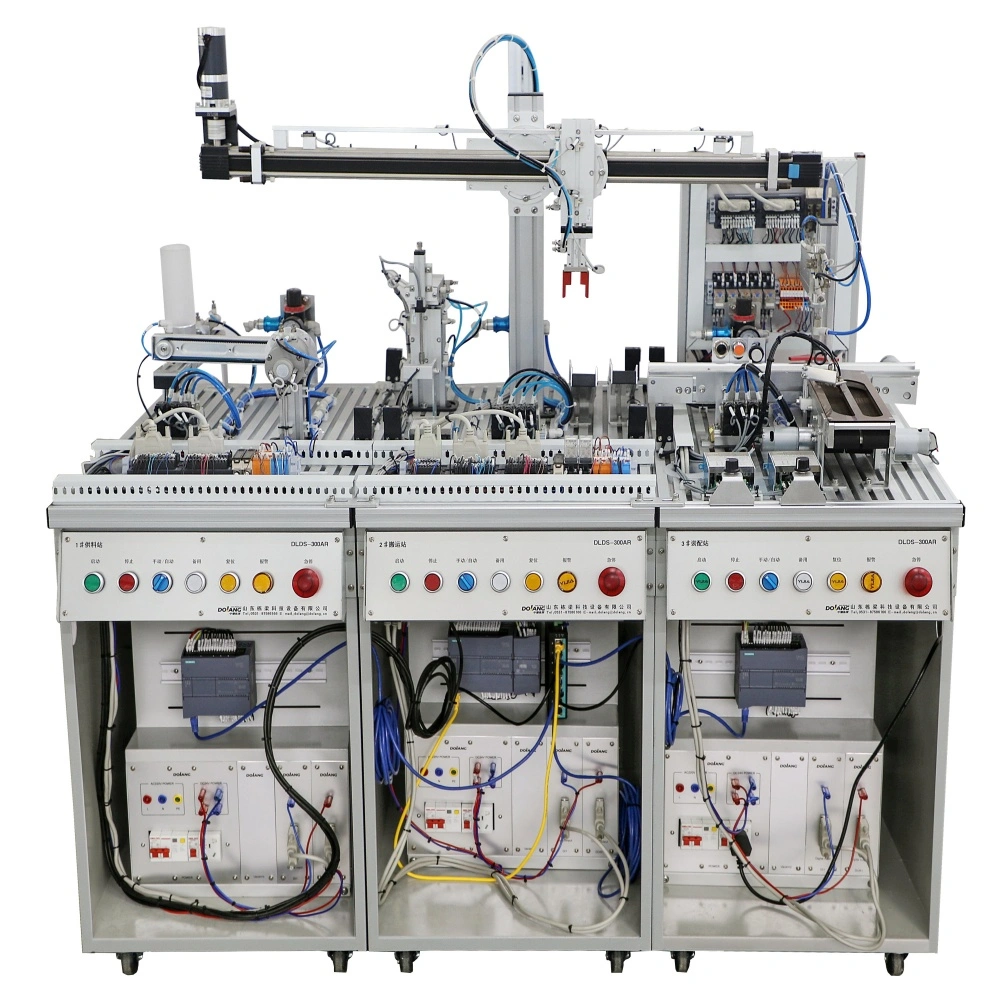

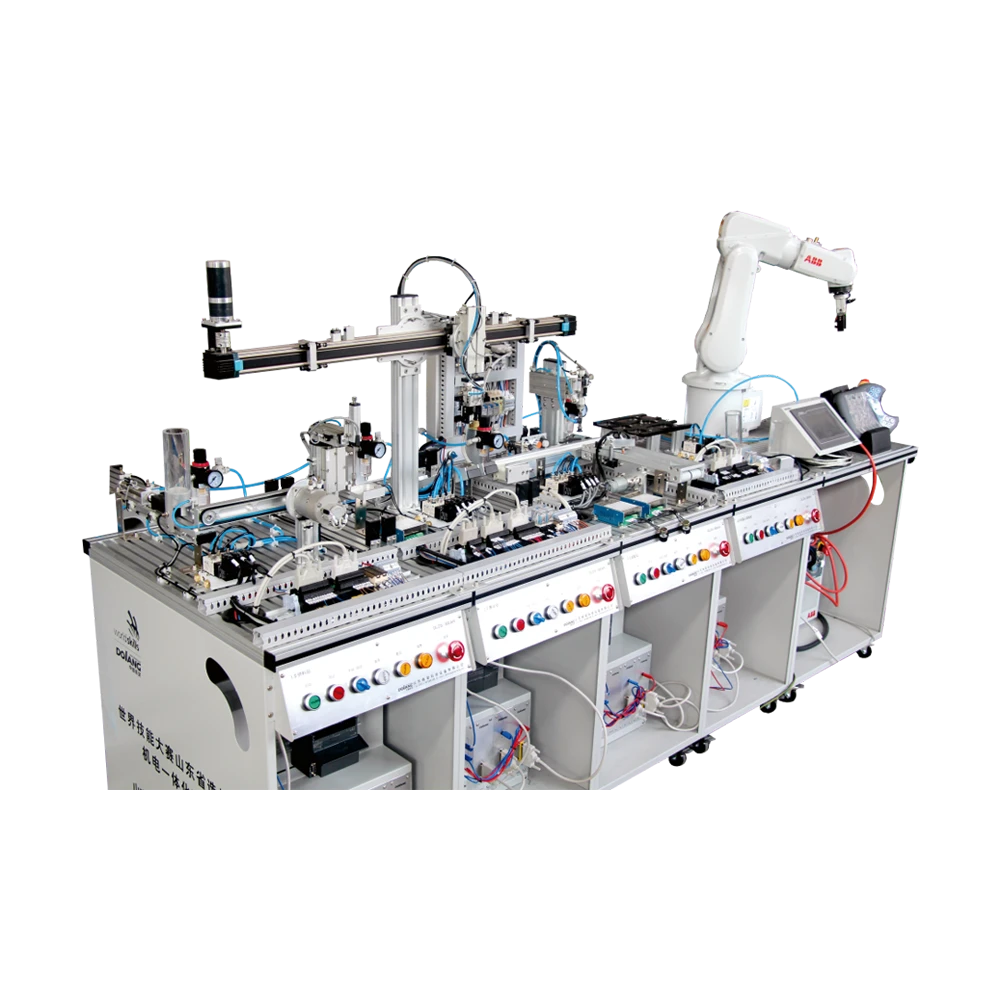

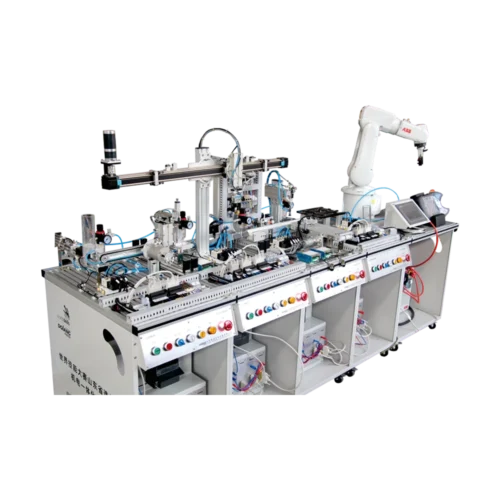

DLDS-300AR is a modular flexible production line training device including an intelligent controller, feeding unit, handling unit, assembly unit, operation panel, control cabinet, and I/O adapter board. The flexible production line can complete a series of actions such as grabbing, transporting and assembling three types of materials. This flexible production line can exercise students’ systematic thinking ability, strengthen students’ hands-on and brain use, and complete the mechanical assembly of each workstation, the assembly of pneumatic components, and electrical appliances. The application of various technologies such as component installation, circuit wiring, PLC programming technology, sensor technology, and electronic technology in professional fields.

2.Technical Parameter

1. Power supply for the main circuit of the electric control cabinet: single-phase AC220V±10%, 50Hz.

2. Power supply for the control circuit of the electric control cabinet: DC24V.

3. Temperature: -10℃~40℃; Environmental humidity: ≤90% (25℃).

4. The overall appearance size is not less than: 1350*790*1390mm (L*W*H);

Feeding unit: Overall dimensions: 450*790*1030mm (L*W*H);

Handling unit: overall dimensions: 1050*790*1400mm (L*W*H);

Assembly unit: Overall dimensions: 450*790*1170mm (L*W*H);

5. Air source pressure: 0.4-0.6Mpa.

6. Overall machine capacity: ≤5KVA.

3.Training items

1. Practical training on wireless communication between stations

2. Application of detection switch

3. Application of various sensors

4. Application of pneumatic components

5. Application of PLC

6. Pneumatic circuit takeover

7. Assembly and disassembly of mechanical parts and pneumatic parts

8. System fault diagnosis and maintenance

9. Cross-site data transfer

10. Ethernet bus technology (Siemens series)

11.Analog input and output control technology

12. Flexible manufacturing system PLC program writing and debugging

13. Mechanical assembly training of feeding unit

14. Electrical installation training of feeding unit

15. PLC program writing and debugging of feeding unit

16. Handling unit mechanical assembly training

17. Electrical installation of handling unit

Reviews

There are no reviews yet.