1. Overview

The DLWD-GZMKV2 electrical device fault assessment and training system is based on the electrical device project of the World Skills Competition and combined with the actual situation of China’s domestic vocational skills competition. It is developed through comprehensive consideration and integrates electrical control systems, smart home systems, and household and commercial lighting. A system-in-one comprehensive practical training and assessment equipment that simultaneously meets the training and assessment requirements for the installation, programming, debugging, fault finding and other modules of the electrical installation project competition. Comply with the technical requirements and standards related to the WorldSkills Competition; cultivate students’ various innovative design abilities, practical operation abilities and engineering practice abilities;

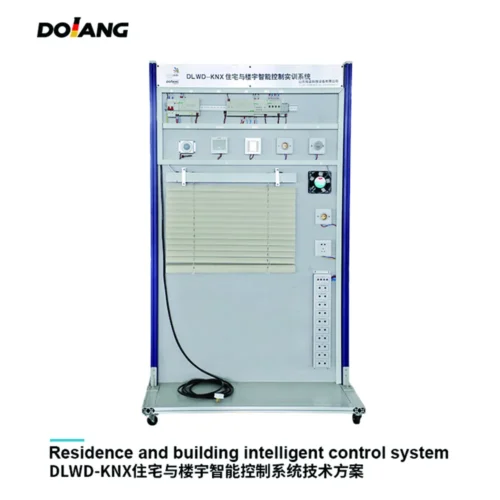

The overall level of the platform is shown in the figure below: Taking the electrical control of electrical installation projects, household and commercial lighting systems, and traditional relay control systems as the entry point, it meets the needs of writing electrical control programs, KNX and lighting system debugging training projects, with three modules as Basic, extended fault finding module for electrical installations.

2. Technical Parameter

(1) Equipment size: 900*900*1860mm;

(2) Equipment power supply: three-phase five-wire system 380V±10% 50Hz;

(3) Working environment: The ambient temperature range is -5℃–40℃;

(4) Device capacity: AC <2KVA;

(5) Safety protection: leakage protection (action current ≤30mA), overcurrent protection, overload protection, emergency stop protection, undervoltage protection;

(6) Relative humidity: <85%;

3. Practical training content can be completed

1) Asynchronous motor inching control circuit;

2) Asynchronous motor self-locking control circuit;

3) Two-place control circuit of asynchronous motor;

4) Three-phase asynchronous motor manual sequential start;

5) Button interlocking three-phase asynchronous motor forward and reverse control circuit;

6) Contactor interlocked three-phase asynchronous motor forward and reverse control circuit;

7) Double interlocked three-phase asynchronous motor forward and reverse control circuit;

8) Forward and reverse jog and start control circuit;

9) Automatic reciprocating control circuit with jog;

10) Asynchronous motor one-way jog and start control circuit;

11) Three-phase asynchronous motor auto-coupling step-down start;

12) DC motor speed control experiment

13) Understanding and wiring methods of KNX components

14) KNX communication connection training

15) Practical training on the use of KNX software ETS

16) KNX programming method training

17) KNX smart curtain controller installation and programming training

18) KNX smart panel installation and programming training

19) KNX dimming module installation and programming training

20) KNX relay control installation and programming training

21) LOGO! installation and programming training

22) Installation and learning of LOGO! programming software

23) LOGO! product installation and wiring training

24) LOGO! Programming instructions-text information function learning

25) LOGO! Programming instructions-timer function learning

26) LOGO! Programming Instructions-Basic Function Learning

27) LOGO! Programming instructions-counter function learning

28) LOGO! Programming instructions-analog function learning

29) LOGO! Panel debugging and menu function learning

30) Inverter unit wiring experiment

31) Learning error information from the inverter panel

32) Frequency converter panel control experiment

33) Inverter panel parameter setting experiment

34) Experiment on manually starting and stopping the motor on the inverter panel

35) Inverter debugging wizard parameter setting

36) Frequency converter debugging multi-speed control experiment

37) Frequency converter debugging macro parameter control experiment

38) Failure assessment and training

Reviews

There are no reviews yet.