1. Overview

DLDS-431 green design and verification platform is mainly composed of digital design unit, industrial network unit, industrial control unit, and intelligent detection unit; it mainly tests students’ design, installation, and debugging of equipment network architecture, data processing applications, and detection system function realization capabilities; examine their mastery and flexible application of industrial Internet technology, electrical control technology, instrument automation technology, mechanical assembly and adjustment, sensor technology, motion control technology, data analysis and many other technologies, as well as safety awareness, craftsmanship, quality and cost control and other professional qualities. At the same time, the operators’ ability to analyze and deal with practical problems, innovation, creativity, organizational management capabilities, etc. at the project site are examined.

2. Process flow

(1) Digital design unit: Deployed with digital twin software and cloud platform, it can realize order management, equipment management, inspection process management, virtual simulation, etc.

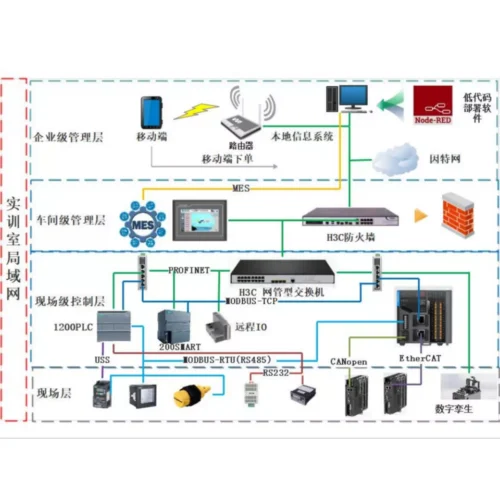

(2) Industrial network unit: user network security management and control, policy control between different networks, etc.

(3) Industrial control unit: network architecture design, control program execution, data processing, etc. between different control units.

(4) Intelligent detection unit: The specific process is roughly divided into: after the system is started, the material is shipped out of the warehouse according to MES or external signal instructions. After leaving the warehouse, a series of characteristics, materials, etc. of the material are detected on the conveyor belt; through comparison with standard data Screening of qualified products and non-qualified products is carried out; if the products are qualified, the order information is written by RFID, and then transported by the robot into the warehouse; if the products are non-qualified, the robot directly places them into the unqualified warehouse. MES statistical detection process data information.

3. Completable training content

1. Application of PLC technology;

1.1. 1500PLC programming operation

1.2. 1200PLC programming operation

2. Application of configuration technology;

2.1. Portal software operation experiment

2.2. Private cloud platform configuration experiment

3. Application of motor drive technology;

3.1. G120 parameter setting experiment

3.2. G120 external terminal control experiment

3.3. G120 speed control experiment

3.4. V90 parameter setting experiment

3.5 V90 position control experiment

4. Application of sensor technology;

4.1. RFID application experiment

4.2. Industrial vision application experiment

4.3. Environmental sensor application experiment

4.4. Other sensor application experiments

5. Industrial software technology application;

5.1. MES software operation

5.2. Digital twin software application

6. Application of bus communication technology;

6.1. PROFINET communication experiment

6.2. MODBUS communication experiment

6.3. S7 communication experiment

7. Edge computing technology application;

7.1. IoT gateway application

8. Application of digital twin technology;

8.1. Rigid body, collision body and other operations

8.2. Kinematic joints and constraint applications

8.3. Coupling sub-applications

8.4. Sensor and actuator applications

8.5. Simulation process control applications

8.6. Virtual debugging collaborative connection

9. Industrial Internet technology application;

9.1. Network architecture planning and design

9.2. Routine operations of layer 3 switches

9.3. Industrial wireless routing applications

10. Application of network security technology;

10.1. Security policy configuration

10.1. Firewall defense function application

11. Intelligent detection system application

11.1. Programming implementation of automatic detection process

Reviews

There are no reviews yet.