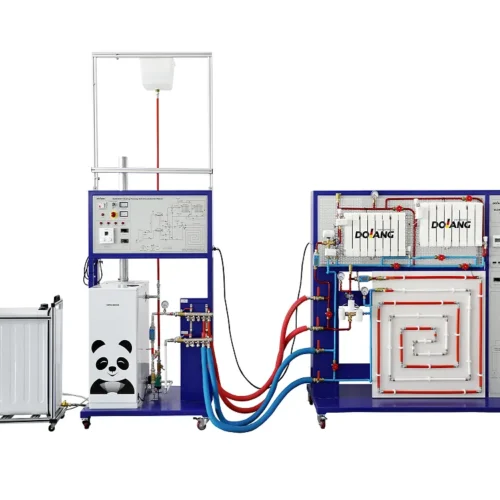

1. Overview

The DLZL-WAC01 training device is powerful. It is not only suitable for the teaching of related courses such as refrigeration technology, refrigeration fluid machinery, principle and maintenance of household refrigeration equipment, cold storage and refrigeration technology in higher vocational colleges and vocational schools, but also can be used as a training base for professional qualification certification such as refrigeration equipment repairer (primary, intermediate, and advanced). In addition, the device also supports the teaching of a variety of refrigeration equipment maintenance-related courses, such as “Refrigeration Equipment Repairer (Advanced)”, “Refrigeration Equipment Principles and Maintenance”, “Refrigeration Air Conditioning Device Operation, Installation and Maintenance”, “Central Air Conditioning Worker (Primary, Intermediate, Advanced)”, “Household Refrigeration Equipment Principles and Maintenance”, etc.

2.Technical parameters

2.1 System footprint: length × width × height ≈ 3.8m × 1m × 1.9m;

2.2 Maximum cooling capacity: 7.5kW;

2.3 Maximum total input power: 6.5kW;

2.4 Rated cooling power: 3.8kW;

2.5 Rated heating power: 2.0kW

2.6 Rated input current: 7A;

2.7 Circulating air volume: 700m³/h;

2.8 Input power: three-phase five-wire AC 380V±10% 50Hz;

2.9 Refrigerant: R22;

2.10 Leakage current: ≤30mA;

2.11 Safety protection measures: It has four protection measures: overvoltage, overcurrent, overload, leakage, and grounding, which meet the relevant national standards.

3. Practical training content can be completed

1) Central air conditioning structure and equipment working principle;

2) Training and assessment of central air conditioning start, operation, stop, and debugging technology;

3) Central air conditioning operation, adjustment operation training and central air conditioning operating conditions, and various operating parameters detection and analysis;

4) Central air conditioning control principle training;

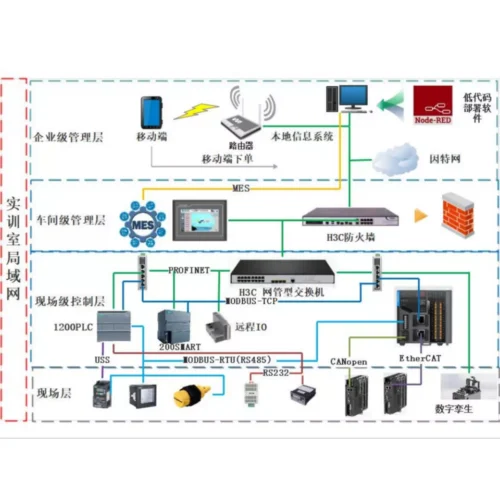

5) PLC advanced programming and PLC installation, wiring and debugging training;

6) Matching pressure transmitter, temperature sensor and corresponding A/D conversion function module, which can collect and monitor the operating parameters of the entire central air conditioning;

7) Adopt configuration technology to realize animation display of central air conditioning operation, operation data display, real-time monitoring, curve analysis, historical record display, alarm, printing configuration and other functions;

8) Fault judgment and equipment fault elimination training;

9) Application and training of data acquisition technology;

10) Sensor and transmitter installation and use training.

11) Power distribution and control system installation methods and standards

12) Common problems of refrigeration system

13) Common problems of control system

14) Common problems of power distribution system

15) High voltage protection training

16) Communication circuit training

Reviews

There are no reviews yet.