1.Overview

This system is based on the relevant documents of the 43rd, 44th and 45th World Skills Competition Plumbing and Heating Project (Plumbing and Heating 15), combined with the actual application status of the domestic plumbing and heating industry and the world skills of experts in various industries. The competition’s plumbing and heating project understanding proposals are carefully designed.

Its purpose is to train and improve the technical ability of students to install piping systems for water supply, drainage, heating, solar energy, etc. for residential and industrial sites.

The system includes installation training modules for stainless steel pipes, copper pipes, aluminum-plastic composite pipes, galvanized pipes and other pipes. The technical standards, skill norms and evaluation system of the WorldSkills Competition are integrated into each training module. It is the preferred training system for vocational colleges and vocational training institutions.

2.System Features and Benefits

1. The system design draws on the relevant standards of the World Skills Competition, and the training content is in line with international standards

This system is a training module based on the World Skills Competition Plumbing and Heating project (Plumbing and Heating 15), drawing on the technical file WSC2017_TD15, consumable list file WSC2017_IL15, and competition topic file WSC2017_TP15 in the World Skills Competition project, and combined with China’s national conditions. . Through practical training, players can broaden their horizons, improve their learning ability, realize the importance of craftsmanship, and feel the connotation of craftsman spirit.

2. The system training content is close to the people’s livelihood

The training content of this system involves the design and installation of heating pipes, gas pipes, hot and cold water pipes, and drainage pipes, all of which are related to the construction content of national life. With the release and implementation of the “National New Urbanization Plan (2014-2020)”, whether it is municipal engineering, civil engineering or industrial construction, the workload of pipeline installation, commissioning and maintenance continues to increase. Therefore, the design and development of this system fully meets the development requirements of the civil construction industry and is close to the needs of people’s livelihood.

3. System training content is related to production safety

The training content of this system pays attention to the control of construction quality, and makes detailed requirements for the connection method and connection quality of each pipe fitting, the installation method and installation quality of pump valves, and the final pressure and leak detection standards, so as to eliminate potential safety hazards after delivery. The importance of production safety is reflected everywhere. At the same time, during the construction process, strict regulations are also made on the personal protection of the players. Goggles and anti-smashing shoes must be worn during the entire construction process; long-sleeved overalls with heat insulation must be worn when hot operations are involved. Gloves. Integrate the matters needing attention in production safety into every aspect of the training.

4. The system training content embodies the craftsman spirit of excellence

The training content of this system requires students to construct strictly according to the drawings, and the assessment standards are made for every operation link.

Meticulous and detailed regulations, and the craftsman spirit of “dedication, leanness, focus, and innovation” are reflected everywhere in the training process, which has injected new vitality into the improvement of my country’s engineering quality.

5. The system design embodies the purpose of energy saving and environmental protection

The training environment of this system is built using high-quality aluminum profiles, with a stable structure and strong rigidity. It can be recycled repeatedly, greatly reducing waste and lowering the impact on the environment. Everywhere highlights the purpose of energy conservation and environmental protection.

6. This system realizes the double docking of training tasks and construction process, evaluation criteria and acceptance criteria

The training tasks are arranged according to the construction process, and the theoretical knowledge and professional skill assessment are integrated into each training session. The theoretical knowledge guides every step of the training at all times. The judging criteria are set according to the construction acceptance criteria, highlighting the dual importance of process and result.

7. The layout design of the training environment is clear and thought-provoking.

The training environment adopts a “Z” layout, but it is not limited to this, and can be easily replaced with a reverse “Z” layout. The two are tightly connected by steel connectors, which not only improves the stability of the environment, but also facilitates handling and assembly. At the same time, it improves the utilization rate of the training room area and saves the training room space.

8. Systematic teaching resources are abundant

The system not only provides detailed operating specifications, intuitive evaluation standards and training courseware, but also has a wealth of operation videos of outstanding players in national competitions. It is convenient for students to self-study, self-training and self-inspection.

3Main components and functions of the system

1 Double-station training platform

1) Aluminum profile “Z” structure, modular combination, easy installation, and can be adjusted to positive “Z” or reverse “Z”, safe and reliable, length 6m, width 4.2m, height 2.5m. It can clearly display the basic principles of piping and heating, which meets the basic requirements of the World Championship.

2) The modular wall adopts high-quality ecological board, which is easy to install and replace, and enables students to flexibly master the installation of pipelines.

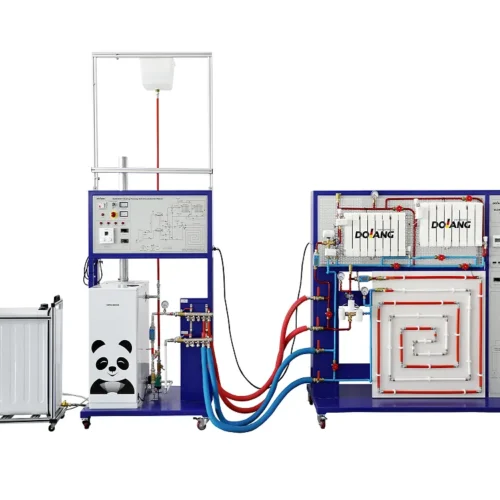

3) The product adopts a double-station design. The A and B sides of each station are the main installation areas for piping and heating engineering. The working area of the A side is 4.2M*2.4M, and the B side is 1.8M*2.4M. It can provide a working environment for the practical training of hot and cold water pipelines, heating pipelines, gas pipelines, gas wall-hung boilers, solar energy, radiators, dual-way heat recovery water tanks and other pipelines and equipment. There is a stepped platform on the C side, the facade is 1.8M*2.4M, and the stepped platform is 0.6M*2.4M, which provides a practical training environment for sanitary system toilets, wash basins, showers and other sanitary equipment.

4) Floor heating training platform, with an area of 1.2M*1.2M, provides a working environment for floor heating pipeline training.

2 Modern bathroom products

First-line brand bathroom products have a wide variety, novel styles, various installation methods, and rich training content. It is convenient to exercise students’ various operation skills.

3. Piping and heating system components that keep pace with the times

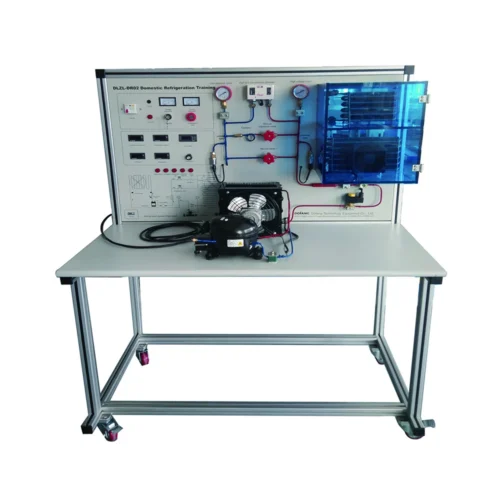

The system is equipped with heating components such as high-quality green gas heat source system, solar heat collection system, solar workstation module, high-efficiency multi-channel heat exchange system, water heating and cooling module, thermal cycle power system, etc., presenting the heating form of thousands of households , embodying unity and representativeness.

4 Training Tools

The training system is equipped with fitter bench, tool trolley, material rack, and is equipped with electric clamps, digital display level, straightening machine, pipe bender, mobile tool trolley, threading machine, etc. for practical training. Tools, and each tool is an excellent product of the first-line brand, which provides a guarantee for the training operation.

5 Consumables for training

Equipped with consumables for double-station training in one month, the consumables also meet the consumption of single-station training competition questions. The specific quantity is subject to the attached list.

6 Supporting Teaching Resources

Teaching resources include not only equipment instruction manuals, but also some national regulations on the pipeline industry.

4. Completion of training projects

Basic theory:

Project 1: National standards and industry norms involved in piping and heating

Project 2: Pipeline and heating related knowledge and related skills learning

Project 3: Principles and specifications of piping system design and drawing

operational skills:

Project 1: Draw a sketch, draw a baseline

Project 2: Fabrication and installation of solar modules

Project 4: Fabrication and installation of heating modules

Project 5: Production and installation of gas modules

Project 6: Fabrication and installation of hot and cold water modules

Project 7: Fabrication and installation of drainage modules

Project 8: Fabrication and installation of floor heating modules

Project 9: Installation of bathroom system

Comprehensive training : capacity space expansion

Reviews

There are no reviews yet.