1. Overview

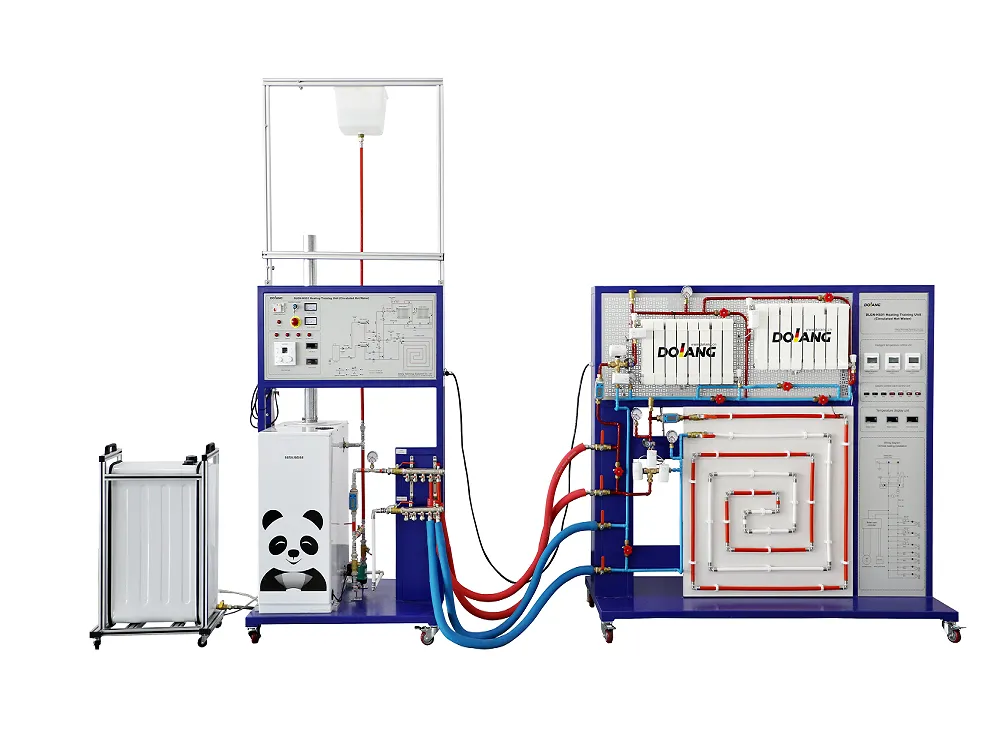

Many experiments can be performed using the training system for setup experiments of the system, as done in the industry, diagnostic experiments, thermal calculations, and thermodynamic experiments. Overview of the water circulation cooling and heating hot water training system, the water circulation cooling and heating hot water training system is a modular, comprehensive, and latest training system with the latest industrial hot water heating equipment and domestic hot water production technology. The teaching and training system adopts the latest technology of microprocessor area control by controlling real or simulated room temperature.

2. Features

(1) Motorized zone control valves, all major components from the main boiler to radiators including real industrial equipment. The frame is made of aluminum profiles and sheet metal parts. The hot water pipes are copper pipes and aluminum-plastic pipes. The hot and cold water are color-coded to better distinguish the water and heat in the system. The main boiler is an oil-fired boiler or gas-fired boiler. Boilers and optionally other types of boilers such as solid fuel burners. Features including a voltmeter, ammeter, digital temperature system display, and electronic water flow meter allow for in-depth thermodynamic studies. All modular units are on wheeled casters and can be easily moved.

(2) The system provides comprehensive training in all major aspects of hydronic heating, including clearly labeled and detailed components, detailed schematic diagrams of piping and control systems, and documentation of all components. The comprehensive training manual covers the basics of hydraulic systems including various system configurations and clear diagrams, theoretical and technical data of hydraulics, information on electrical and electrical wiring, and a complete laboratory manual. This manual provides a book covering technical data and a range of experiments that can be performed by teachers or students themselves after familiarizing themselves with the equipment.

(3) Room temperature simulation: The system includes an innovative system that can simulate room temperature. This enables experiments independent of ambient temperature. The system can be easily switched between real ambient temperature and a simulated single room temperature. This feature is a modular zone, so each individual zone of the system can be set to a different simulated room temperature. The simulated temperature for each zone provides greater insight into the system characteristics of the experimental boiler and zone control of various room temperatures.

(4) Modular system: The modular system can quickly and easily replace various modules. The main boiler is connected to the various modules by hoses and shut-off valves, so the modules can be easily isolated and replaced without water leakage. This also enables the main boiler unit to be used in a variety of training applications.

(5) Some of these experiments include: fuel system inspection and filling procedure, water system inspection, filling and draining procedure, electrical system inspection, and system start-up procedure.

3. Parameter

Power supply: single-phase 220V±10%, 50Hz, 16A;

The two tables have casters: 4, 2 of which have brakes.

Reviews

There are no reviews yet.