1. Overview

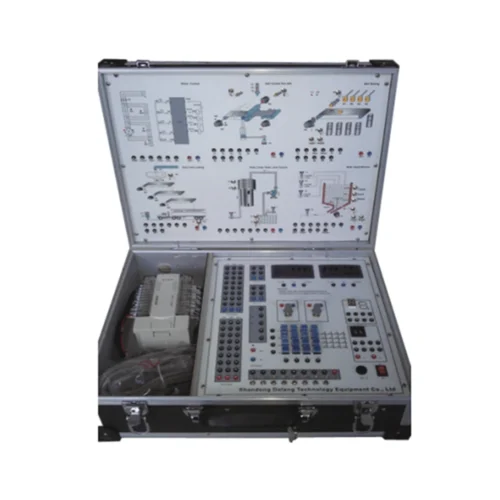

The DLIOT-B114B industrial automation network training platform is developed based on Siemens’ fully integrated automation PLC control system. This industrial automation training platform is a comprehensive training device developed for higher education and vocational and technical education. It is suitable for teaching in mechatronics, automation and other majors in various vocational schools (colleges) and for those engaged in related professional technologies. Practical training of personnel. This system can not only be used as an automated and networked teaching and training system, but can also be combined with subsystems to form a networked classroom.

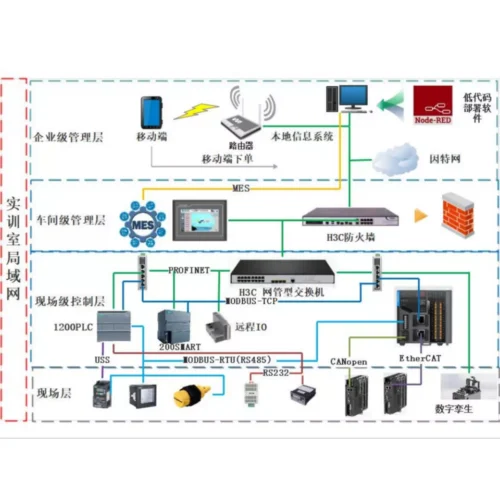

2. Introduction to Laboratory Network

The entire training lab can be seen as an automated workshop, and each training platform (student machine) can be seen as a workstation within the workshop. Each workstation includes various automation equipment, and each workstation device is connected to communicate and coordinate work through the PROFINET bus. The operation status of each workstation equipment can be coordinated by connecting to the enterprise level industrial Ethernet (training room LAN). The teacher machine can also monitor the operation of various student machine devices through industrial Ethernet. Connecting the training room LAN to the school LAN can enable teachers to remotely monitor various training equipment outside the training lab.

3. Practical training content can be completed

1. Design comprehensive practical training network and systematic experimental projects

2.S7-1500PLC programming and communication training

3.S7-1200PLC programming and communication training

4.200smart programming and communication experiment

5. MODBUS-RTU communication experiment

6.Basic programming exercises for the host computer VINCC configuration software

7. PC reading and writing remote PLC experiment

8.Industrial Ethernet usage training

9. Free port serial communication experiment

10. Standard transmission G120 inverter basic speed regulation, multi-speed speed regulation, PN communication speed regulation experiment and motor control experiment

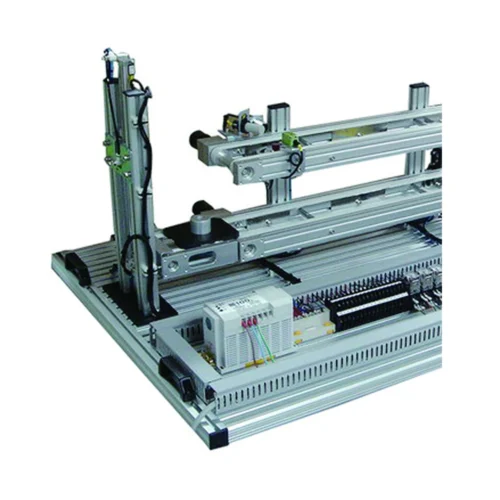

11. Touch screen programming and communication experiment

12. Practical training on cooperation and control through network communication between PLC, frequency converter, host computer (WINCC), touch screen and other equipment

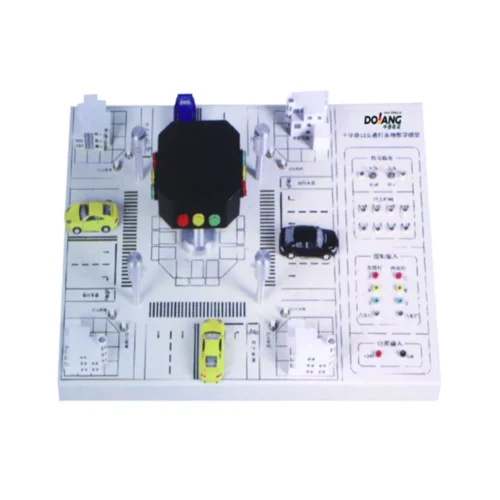

13. Automatic and manual control of traffic lights

14. Controllable experiment of traffic light opening and closing time

15. Automatic control of steel rolling mill

16. Automatic control of water level in water tower

17. Water tower water level control experiment with self-diagnosis

18.G120 inverter parameter setting training

19.G120 multi-speed training with external button control

20.G120 stepless speed regulation based on external potentiometer

21.DP communication

Reviews

There are no reviews yet.