1. Overview

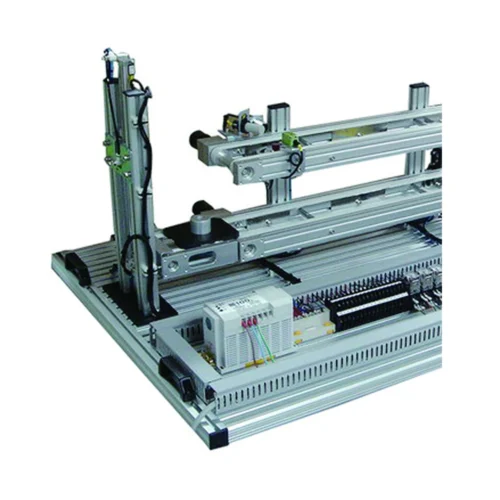

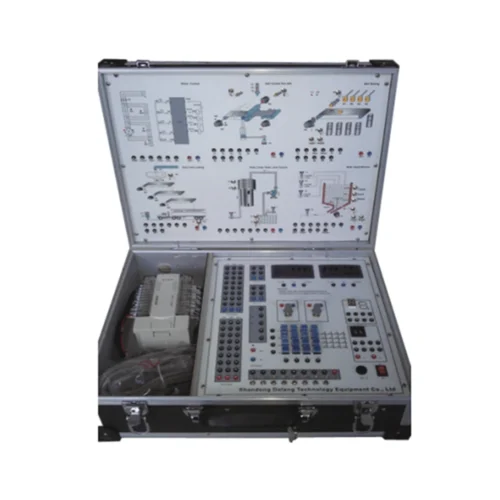

The DLDS-532 industrial network intelligent control and maintenance system consists of an automatic feeding unit, an intelligent sorting unit, an intelligent warehousing unit, a data management unit and a data management center.

Through this system, it mainly tests students’ knowledge of industrial networks, automatic control, intelligent manufacturing networks, industrial data transmission, etc., as well as the design and integration of industrial network intelligent control systems, selection, construction, networking, debugging, and digital monitoring of industrial network intelligent control systems. Operation and maintenance capabilities, as well as professional qualities such as safety awareness, craftsmanship, quality and cost control; at the same time, the operators’ ability to analyze and deal with practical problems at the project site, innovation, creativity, organizational management and team coordination abilities are examined.

2. Technical Parameter

1. Working power supply: AC220V±10%, 50Hz;

2. Rated power: ≤5KW;

3. Dimensions: The area is about 6000×2500×1850mm (L×W×H);

The overall dimensions of the equipment are approximately 4700×1100×1850mm (L×W×H);

4. Working environment: temperature 5℃~+40℃, relative humidity <85% (25℃);

5. Safety protection: It has multiple protections such as short circuit, overload, alarm and emergency stop.

3. Equipment characteristics

1. Device selection: The main devices used in the platform are all selected from well-known international and domestic brands, with advanced technology and high market occupancy.

2. Standardization: The platform is designed and developed and tested in accordance with national safety standards and specifications related to mechanical and electrical equipment.

3. Modular design: Using modular design, each module can complete practical training independently, and can also be flexibly configured and combined according to user needs; students can use their innovative thinking to innovate and transform the original production process. ; On the premise of mastering basic knowledge, further improve students’ enthusiasm, practical ability and innovative thinking.

4. Intelligent design: The equipment can self-monitor, monitor its own status and external environment during operation, record data and analyze the generated data.

5. Open design and strong scalability: Fully consider the future hardware expansion, function expansion, application expansion, integration expansion and other multi-level extensions of the system to facilitate users to better reuse the platform during secondary development.

6. Combination of software and hardware, virtual and real linkage: Through digital twins, digital electromechanical modeling is used to replace physical equipment for simulation debugging, accelerating the integration between virtual design and physical manufacturing, and reducing complexity risks.

7. Integrate the latest technologies and have strong comprehensiveness: Integrate the key points of intelligent manufacturing such as intelligent sensing technology, intelligent warehousing technology, automatic identification technology, digital twin technology, network security technology, collaborative manufacturing technology, digital middle-end technology and remote operation and maintenance technology. technology, achieving a high degree of unification of equipment automation, lean production, and management informatization.

4. Achievable assessment tasks

3.1. Application of PLC technology;

3.2. Application of configuration technology;

3.3. Application of motor drive technology;

3.4. Application of sensor technology;

3.5. Industrial software technology application;

3.6. Application of bus communication technology;

3.7. Application of digital mid-end technology;

3.8. Application of collaborative manufacturing technology

3.9. Edge computing technology application;

3.10. Application of digital twin technology;

3.11. Industrial Internet technology application;

3.12. Application of Internet of Things technology;

3.13. Application of network security technology;

3.14. Application of data cloud platform technology.

Reviews

There are no reviews yet.