1. Overview

At present, the training device can carry out the actual hands-on operation of the electrical control circuits listed in the textbooks of “Elementary Maintenance Electric Refrigeration Technology” and “Intermediate Maintenance Electrician Technology”, so that after the operation training, the students have been improved in the following skills:

(1) Familiar with the structure, principle, installation, and use of common low-voltage electrical appliances;

(2) Understand how to use graphic symbols and text symbols in circuit diagrams, and be able to follow the physical layout,

(3) Master and use the professional knowledge learned in books to independently complete the detection and debugging of circuits

2. Componenets

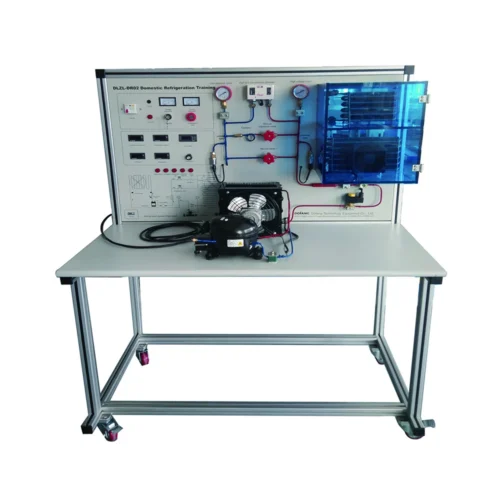

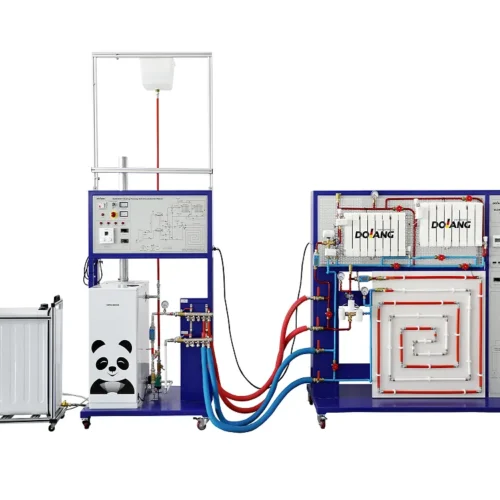

1. The training device is built around an aluminum profile frame that includes a silk-screened panel to mount the components and a profiled base plate for easy installation.

The equipment chassis is equipped with castors with brake locks. Each system is fully installed with plumbing and electrical connections so that it is ready to operate.

Components are clearly laid out and labeled for easy identification, and refrigeration schematics and circuit schematics are provided to guide teaching.

The refrigeration pipeline is color-coded in red and blue. Red represents high pressure, and blue represents low pressure to indicate the state of the refrigerant. There is also a sight glass to monitor the cooling state of the refrigerant at this position. Refrigerant: R22 or equivalent.

Components list:

1) Hermetic compressor: Power supply: single-phase 220V±10% Power: 1HP Refrigerant: R22

2) Condenser: Power supply: single-phase 220V±10%

3) Evaporator: Power supply: single-phase 220V±10%

4) Humidifier device: Power supply: single-phase 220V±10% Capacity: 2.3 liters5) Heater: Power supply: single-phase 220V±10%

Power: 500W

6) Evaporation box

7) Liquid storage tank: capacity: 1 liter

8) High pressure gauge: pressure: 0~3.8Mpa

9) Connection method: bell mouth threaded connection

Connection pipe diameter: Φ6

10) Low pressure gauge: Pressure: 0~1.8Mpa

Connection method: bell mouth threaded connection

Connection pipe diameter: Φ6

11) Expansion valve

12) High pressure controller

13) Low pressure controller: connection method: bell mouth threaded connection

Connection pipe diameter: Φ6

14) Sight glass: welding type

15) Manual valve: connection method: bell mouth threaded connection

Connection pipe diameter: Φ6

16) Solenoid valve: Power supply: single-phase 220V±10%

Connection method: welding

3. Training Contents

1. All the components used in the air conditioning training equipment can be known.

2. State of the refrigerant in the compression refrigeration cycle can be shown.

3. Heating, cooling, humidification, and dehumidification processes can be mastered.

4. Learning cooling effect, equipment efficiency, and so on

5. Computer can collect the data from the refrigeration system

Reviews

There are no reviews yet.