1. Overview

DLIM-DT01 digital twin technology training equipment can create a virtual simulation system with actual interaction functions according to the requirements. The simulation system can realize physical performance, mechanical structure, and action function consistent with the actual environment. That enables the parallel development of mechanical and electrical design on the simulation system, eliminating the gap in the traditional development process communication of PLC, touch screen, industrial robot, AGV, laser marking machine, servo motor, stepping motor, and other equipment.

2. Technical Parameter

Model: DLIM-DT01 series

The DLIM-DT01 digital twin technology application platform can seamlessly map the real physical production line into a 3D digital model. By using advanced simulation technology and information technology, the platform can achieve the following:

1. Design twins: Students can build different industrial production scenarios based on the smart factory material library provided by the software or 3D industrial models designed by themselves, and perform layout, simulation debugging, and optimization;

2. Product twinning: Through real PLC and HMI drive virtual industrial production scenario, realize parallel verification, debugging, and optimization of a control program.

3. Performance twinning: By extracting the sensor and PLC data of real industrial production scenarios, virtual industrial production scenarios can reflect the production status, working conditions, and locations of real production scenarios in real-time to conduct more realistic and comprehensive detection of unpredictable situations to improve business performance.

Operate workbench technical parameters:

1 Temperature: +5—+45°; Ambient humidity: ≤85% (25°C).

2 System area: not less than 850mm×730mm×1500mm.

3 Machine power: about 120VA.

4 Input power supply: single-phase three-wire AC220V±10% 50Hz.

5 Material: sheet metal, surface sprayed.

Digital twin technology application platform

For detailed parameters, please consult us.

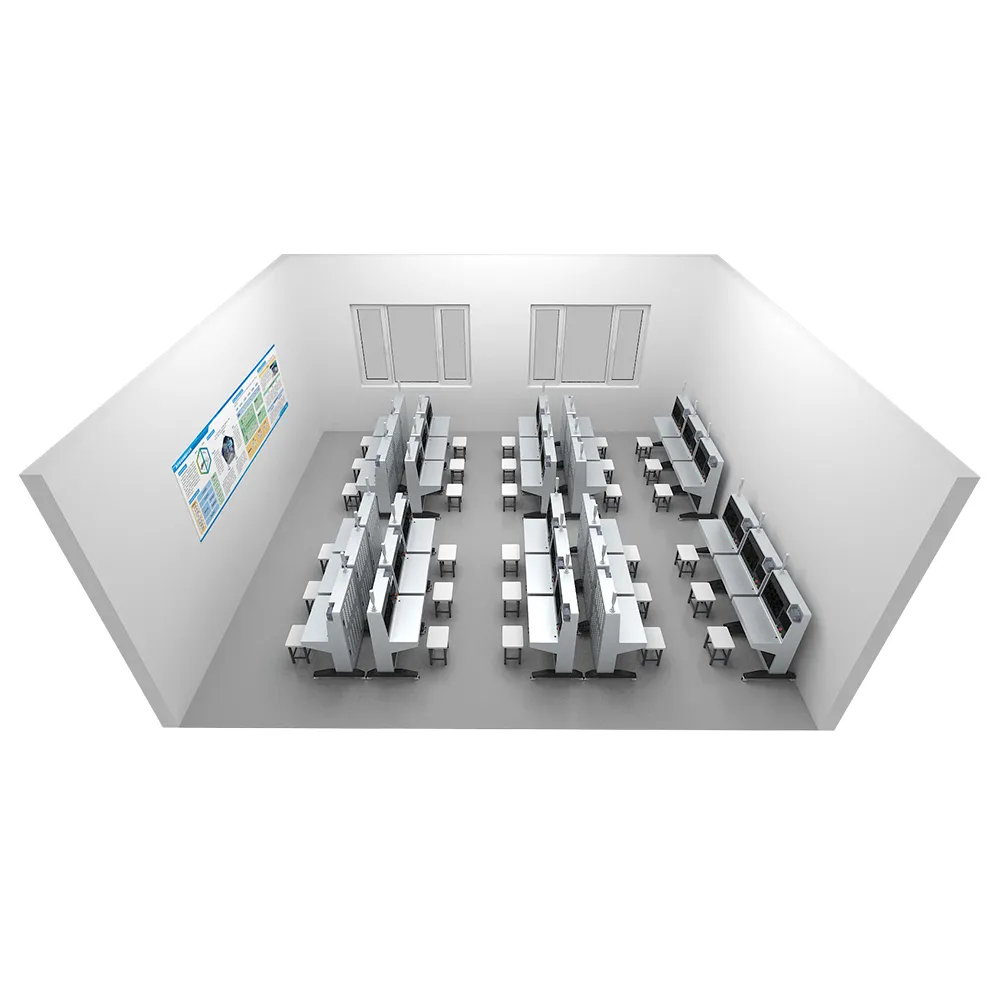

DLIM-DT01A

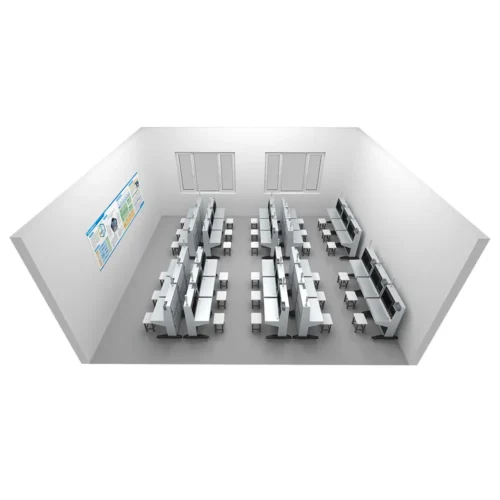

DLIM-DT01B

3. Digital Twin Technology Training Contents

1) program and commission of PLC

2) HMI commissioning

3) Recognition and use of industrial robots teach pendant

4) Offline programming and commissioning for industrial robots

5) PLC and 6-axis industrial robot TCP/IP communication

6) Communications in equipment MES system &PLC module

7) How to use the vision technology module

8) How to build and layout digital 3D model

9) What is communication and commissioning of an Industry network

10) MES software usage

11) Mechatronics Co-Simulation included mechanical intervention, Mechanism Kinematic Validation, Mechanism Dynamics Validation

12) Joint virtual commissioning of teaching device automation consisting of PLC programming, touchscreen

Reviews

There are no reviews yet.