1. Overview

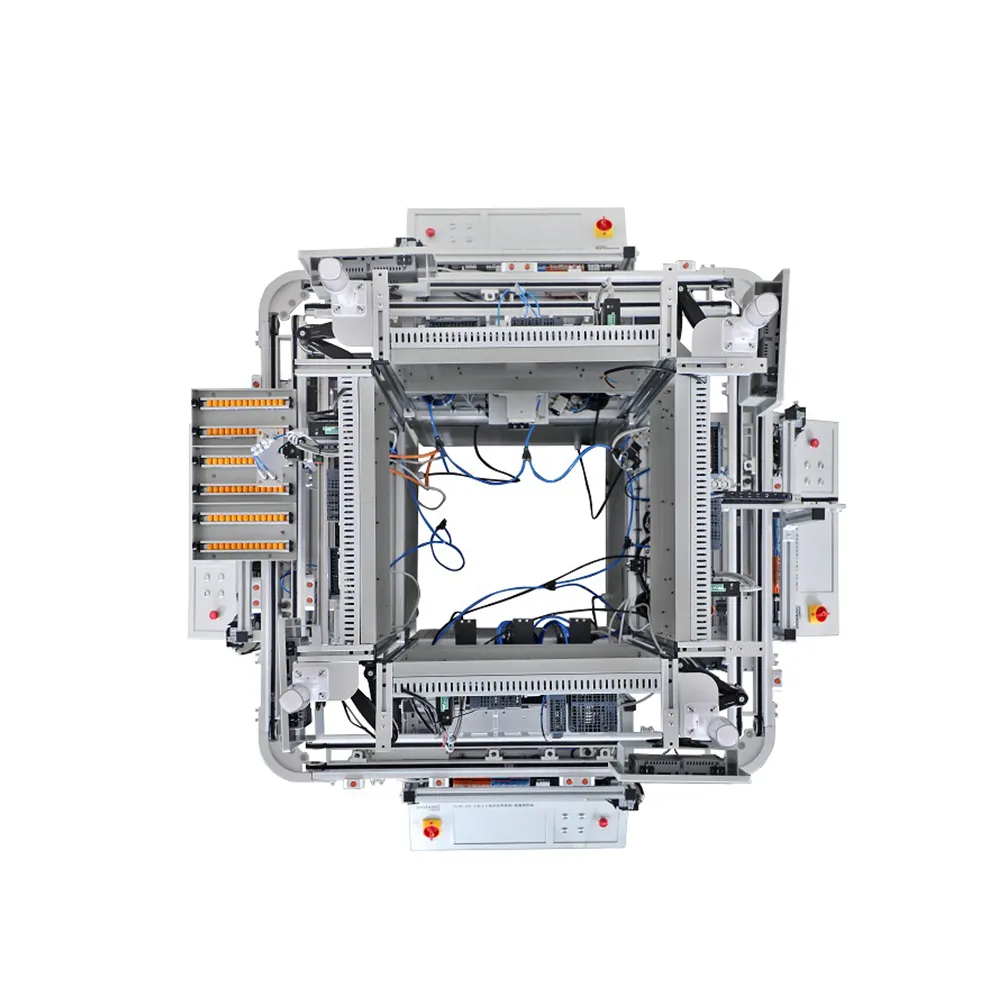

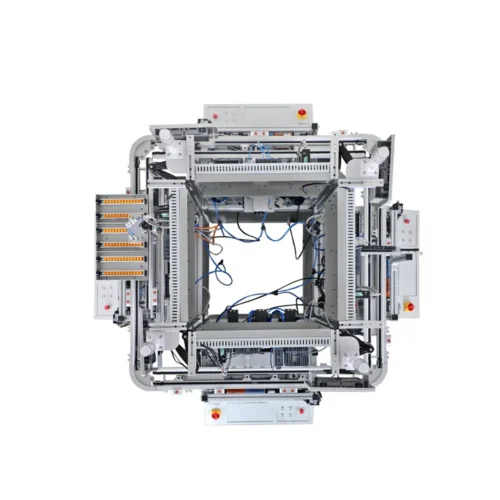

This Industry 4.0 technologies application training system is closely related to the latest development trend of Industry 4.0 manufacturing. It integrates advanced technologies such as Internet+, PLC control technology, smart sensor, digital twin simulation, logistics technology, IT technology and safety, and so on.

2. Composition And Function

The hardware of this Industry 4.0 technologies training system includes several stations such as bookmark feeding station, bottom box feeding station, box covering station, and warehousing station. The software includes MES and a digital twin system. The equipment can complete the bookmarks’ personalized customization, and students can master and learn the skills of industry 4.0.

3. Industry 4.0 technologies Training Contents

1. Sensor detection technology: optical fiber, photoelectric, and inductive sensors commonly used in industrial automation. Students can know each sensor on the equipment and master the use method of each sensor.

2. Electrical control system: the electrical drawings are designed according to industrial standards. Students can learn circuit principle analysis, PLC I / O address check, and equipment circuit analysis methods on this equipment.

3. Motor driving technology: servo motor, stepping motor, AC motor, and driver. Students can understand and master the use methods of each motor on this equipment.

4. Siemens PLC technology: students can practice PLC wiring, programming, and debugging on this equipment.

5. RFID Technology: installation and debugging of RFID.

6. Internet of things technology: installation and testing of industrial Internet perception layer equipment, connection and configuration of Internet of things network transmission layer, deployment of the industrial Internet application layer, and joint commissioning of industrial Internet collaborative manufacturing system.

7. Configuration technology: students can practice the programming of Siemens configuration software and the communication between configuration software and PLC on this equipment.

8. System maintenance and fault detection technology: this part focuses on the contents and methods of daily maintenance of mechatronics equipment, as well as common fault analysis and troubleshooting methods.

9. Digital twin technology: digital 3D model building and layout, virtual PLC debugging, virtual production line beat optimization, etc.

10. MES technology and application

11. Logistics technology: not only transfer, handling, assembly, and storage technology but also identification, data transmission, and tracking technology.

12. IT technology: mainly including network planning, network cabling, firewall, VPN, gateway, router setting, etc.

13. Information security: the two LANs are mainly interconnected. The network firewall is configured, and the gateway provides filtering and security functions

Reviews

There are no reviews yet.