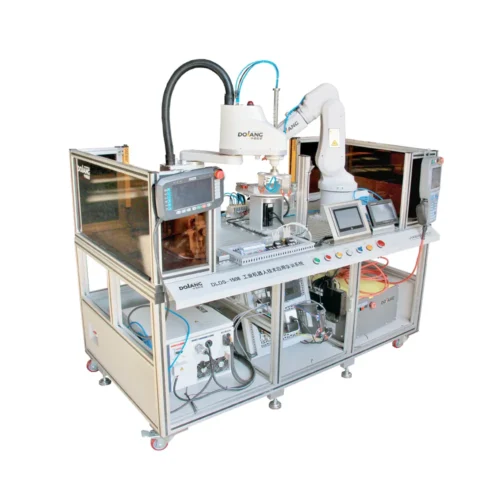

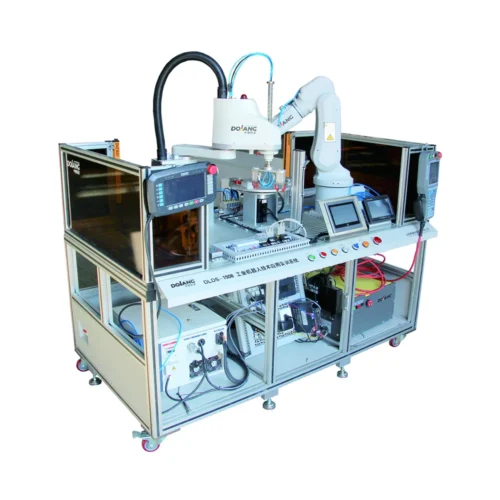

1.Equipment Overview

In vocational education and continuing education, courses related to intelligent power control have become one of the important courses for training students and related practitioners in electrical majors. The construction of training rooms can provide students with a learning environment that is closer to actual work scenarios, helping them better understand and master the core knowledge and skills of power control and maintenance. At the same time, training rooms can also undertake various training tasks to cultivate more highly skilled talents for society.

2.Technical Parameters

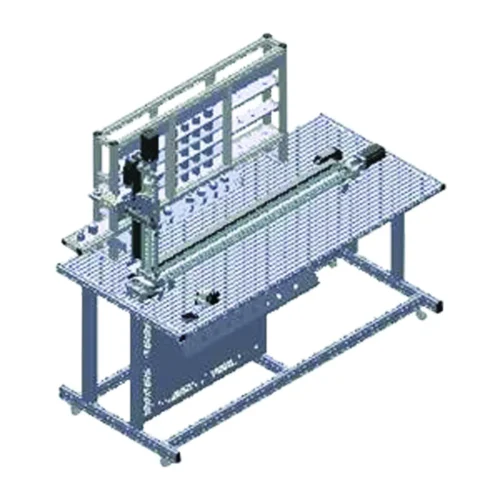

- Working power supply: AC220V±10% 50Hz

- Rated power: ≤1.5kW

- Reference unit size: single box about 700*430*400mm (±10%)

- Power supply control: Use automatic air switch to switch on and off the power supply, equipped with short circuit protection system, leakage protection system, grounding protection, emergency stop protection, etc.

- Single-phase three-wire AC 220±10%: safety sheath socket output and three-pole multi-function socket output DC regulated power supply: DC24V/3A

3.Features

- Portable suitcase design, small size, saves teaching area and is easy to carry

- The components are embedded and the input and output of all components are connected to the K2 type safety socket. They can be connected with test wires when in use.

- The equipment is equipped with system power indication, leakage protection, overload, short circuit protection, etc. to strengthen the protection function for personal safety.

- The equipment logos are all printed on the panel using screen printing technology, and the logos are clear and easy to identify.

The device uses safety test wires and connectors customized by our company, which exceed the US military MIL standard and international IEC standard. No electric shock will occur when touched by human hands.

4.Training Process

- of TIA portal programming software

- PLC basic programming instruction learning

- Basic instructions in TIA Portal – Bit logic and timer instructions

- Basic TIA Portal instructions – counter and comparator instructions

- Basic TIA Portal instructions – Mathematical function instructions

- Basic TIA Portal instructions – move operations and conversion instructions

- Basic instructions of TIA Portal – Program control and shift and loop instructions

- TIA Portal Extended Commands – Date and Time Commands

- TIA Portal Extended Instructions – String and Addressing Instructions

- TIA Portal process instructions – axis parameter instructions

- PLC Project Configuration

- Siemens servo positioning control training

- Siemens debugging software usage training

- Painting of touch screen HMI screen

- Wiring and debugging of servo motor driver

- Servo motor driver parameter settings

- Pulse positioning control of servo motor driver and PLC

- Inverter start/stop, forward/reverse control based on BOP panel control

- Inverter start and stop exercise based on external signal control

- Inverter forward and reverse rotation exercise based on external signal control

- Frequency converter multi-terminal speed training based on external signal control

- Open-loop speed regulation exercise of frequency converter based on external signal control

- Frequency converter start/stop, forward/reverse programming based on PLC control

- Multi-terminal speed programming of frequency converter based on PLC control

- Programming of frequency converter open-loop speed regulation based on PLC control

- PROFINET communication based on PLC control and inverter

- PLC-based crossroad traffic light simulation control training

- PLC-based control of the light tower simulation control training

- PLC-based digital tube analog control training

- PLC-based control of automatic packaging production line simulation control training

- PLC-based water tower water level simulation control training

- PLC-based automatic feeding and loading simulation control training

- Digital twin technology application-rigid body, collision body and other operations

- Digital Twin Technology Applications–Kinematic Pairs and Constraint Applications

- Digital Twin Technology Application–Coupling Application

- Digital Twin Technology Applications–Sensor and Actuator Applications

- Application of digital twin technology–simulation process control application

- Digital Twin Technology Application–Virtual Debugging Collaborative Connection