1. Overview

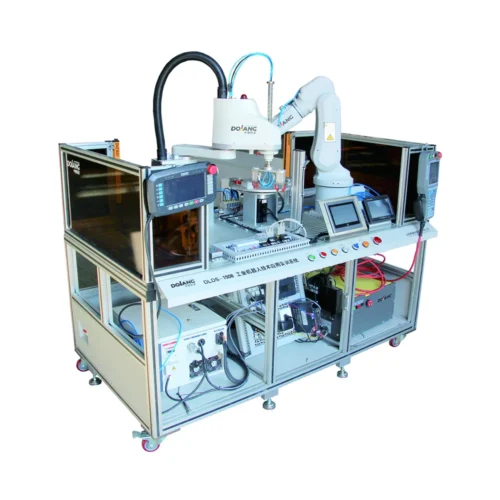

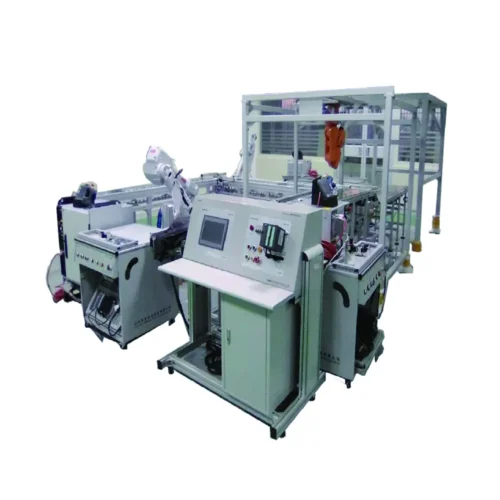

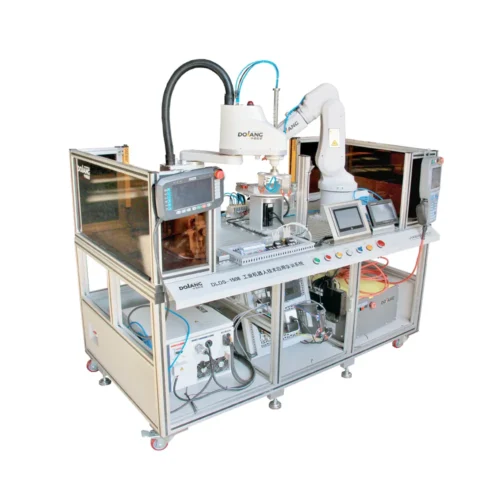

A modular industrial robot open training system is used to solve the problem that the functional structures of existing training equipment are fixed on an operating platform, the control loops have been connected in advance, and the secondary development of peripheral systems cannot be supported. During the actual training operation of students, it is easy to damage peripheral equipment that is not related to the current training project due to various reasons; the practical ability and innovative ability are not well exercised, and they can only practice a single programming and other problems.

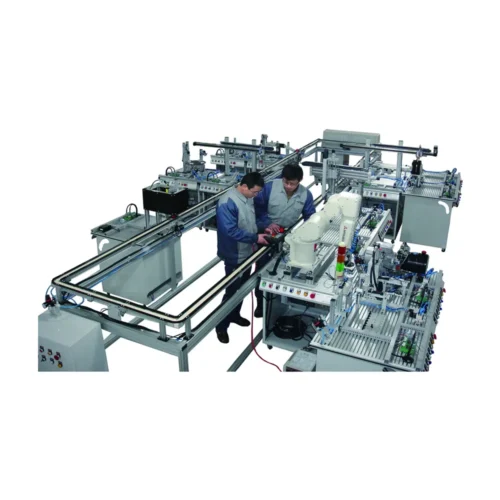

The engineering education equipment is widely used in technical vocational schools, it is used as Technical Training Aids for Robotics Technician Training

2. Functional features

1) Input power: single-phase three-wire system AC220V±10% 50Hz,

2) Working environment: temperature -10℃-+40℃, relative humidity <84% (24℃), no condensation of water drops above sea level <4001m

3) Power supply control: automatic air switch on and off the power supply, with short-circuit protection and over-current protection system.

4) Dimensions: 1700 mm×900mm×1600mm

3. Practical training that can be completed

3.1. Basic aerodynamic experiment

Basic knowledge of control technology and related terms: control loop, signal flow, composition and drawing of loop diagram

The structure and principle of pneumatic components

The pneumatic basic control loop

Safety protection measures

Analysis and troubleshooting of experimental loop failures

3.2. Basic circuit experiment

Basic knowledge of electrical

Structure and function of electrical components

Fault analysis of the control loop

Structure and function of electrical components

Electrical self-holding circuit

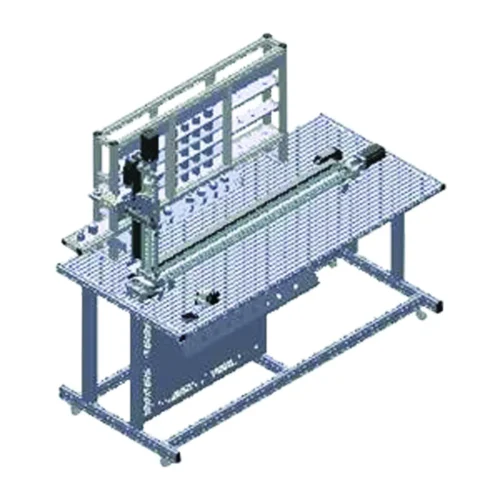

3.3. Mechanical structure and integrated wiring training

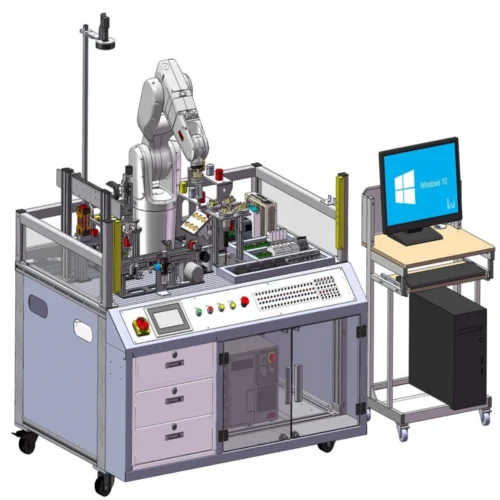

In modular functional design, students can carry out multiple disassembly and assembly experiments under the correct use, improve students’ intuitive cognition and skill operation level of mechanical products, so as to achieve the purpose of teacher teaching and realize the true mechatronics teaching significance.

3.4. PLC control technology experiment

Programmable controller hardware recognition and wiring

Basic instruction exercises of programmable controller

Programmable controller communication practice

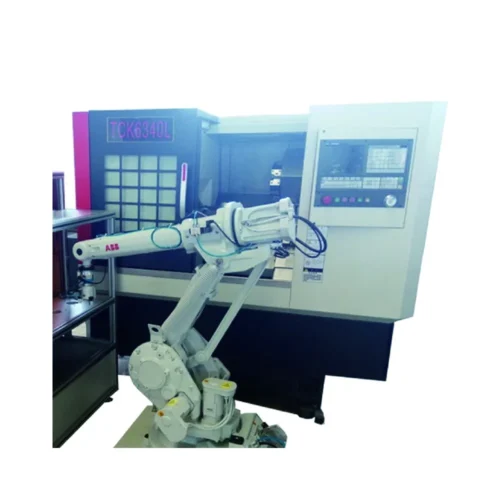

3.5. Basic operation and programming of industrial robots

Installation and wiring of the industrial robot body and the controller;

Initialization and parameter recovery of industrial robots;

IO communication between industrial robot and PLC;

IO wiring of industrial robot;

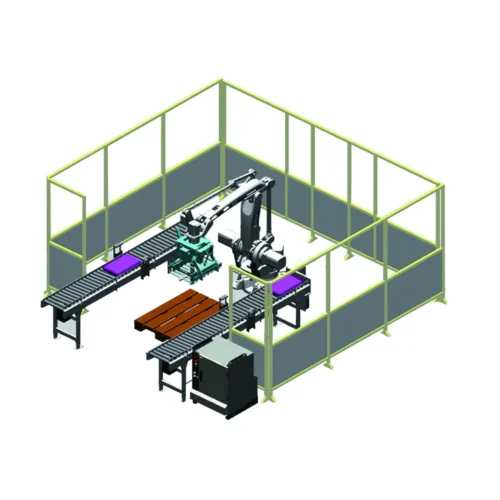

Installation and wiring of industrial robot palletizing applications;

Selection and design of industrial robot fixtures;

Programming and debugging of industrial robot palletizing applications;

Installation and wiring of industrial robot handling applications;

Programming and debugging of industrial robot handling applications;

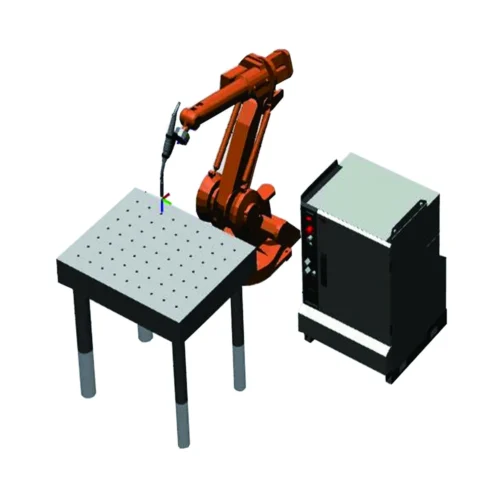

Programming and debugging of industrial robot trajectory curve

Industrial robot detection, arrangement, application, installation and wiring;

Industrial robot detection and arrangement application programming and debugging;

Reviews

There are no reviews yet.