1. Overview

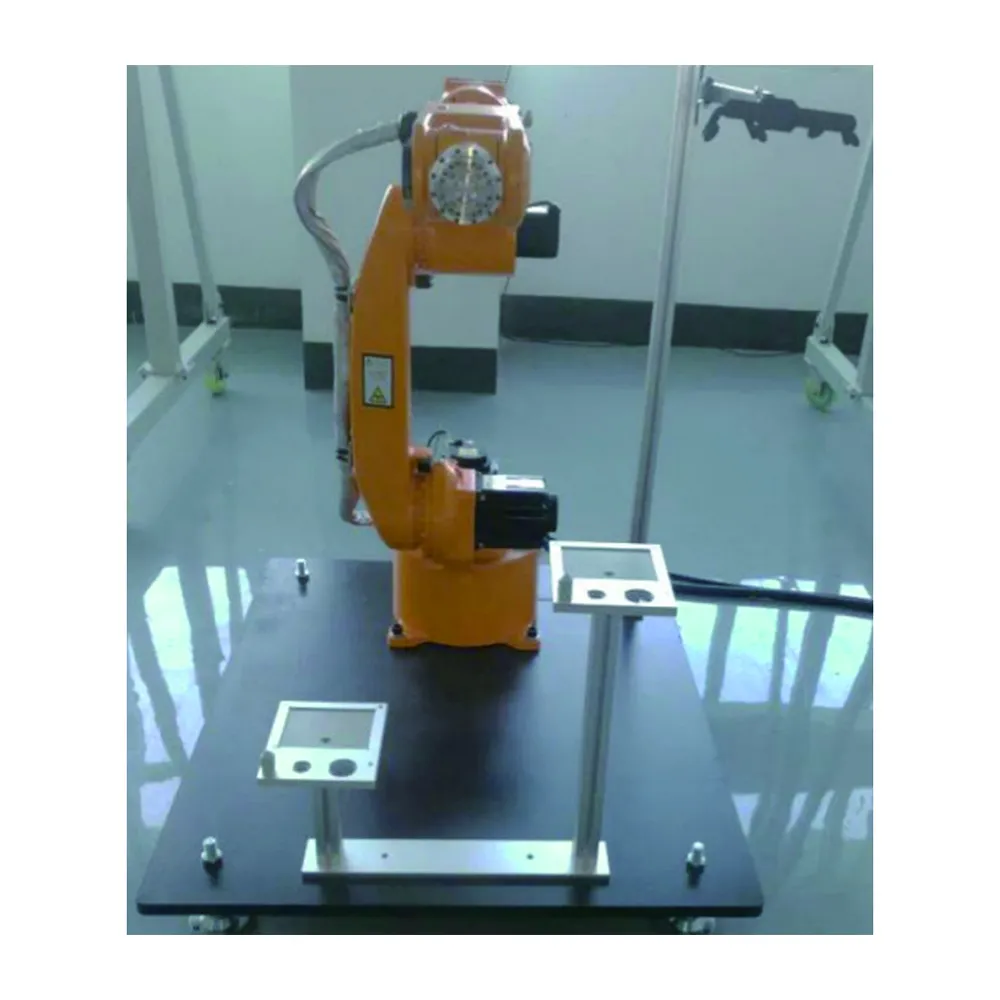

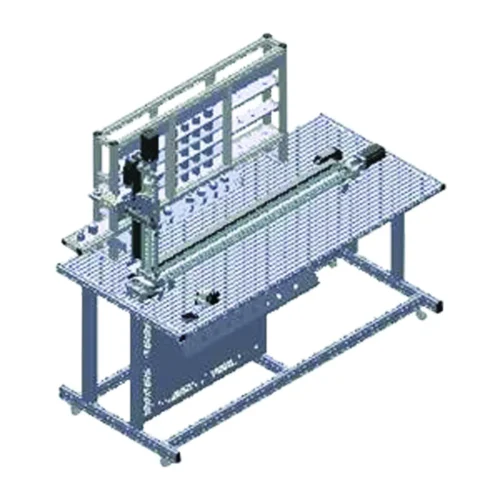

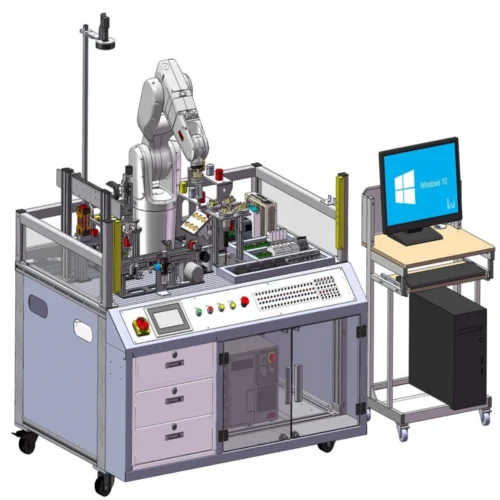

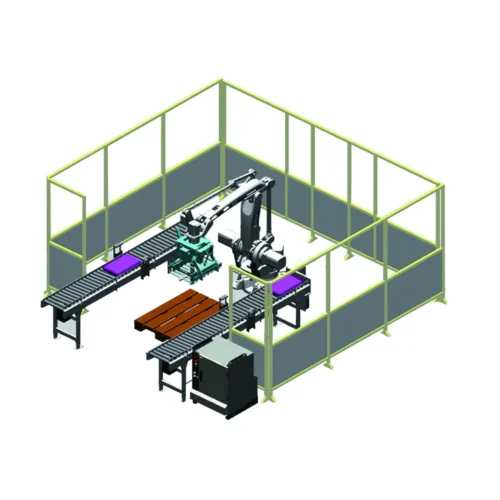

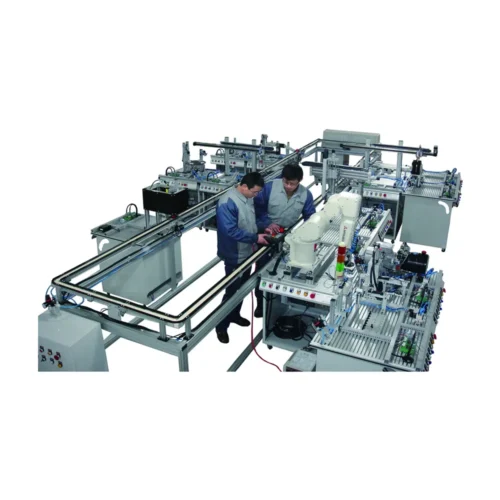

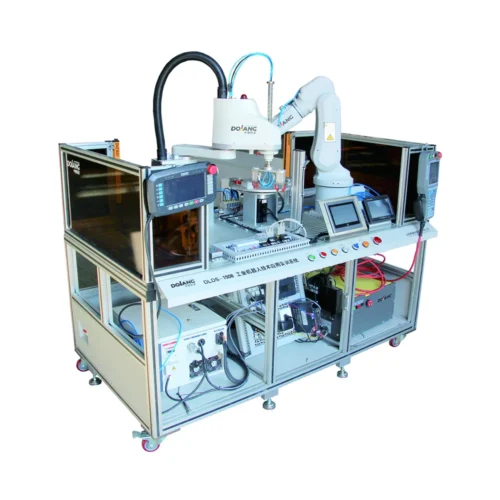

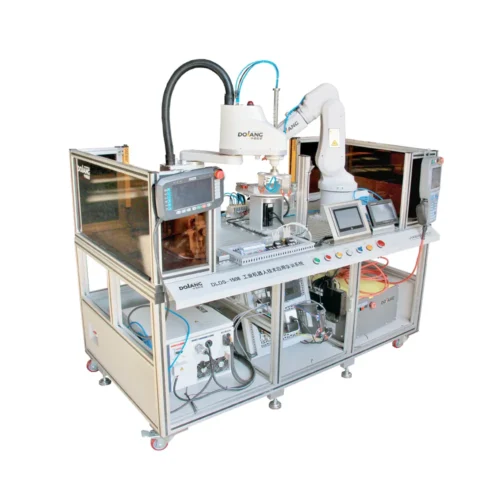

The DLIR-106 industrial robot training system is a typical robotics training system for robot disassembly, operation, and maintenance in technical education. Which consists of an industrial robot body and base, electronic control disassembly and assembly platform, disassembly and assembly parts cart, disassembly and assembly turnover device, robot component placement tooling, mobile gantry crane, work table, tool cart, palletizing module, Pneumatic system, tool kit, teaching machine and bracket, safety protection, industrial robot virtual disassembly training simulation software, etc.

2. Technical Parameters

DLIR-106 Workstation operating environment: areas with less dust, oily fume, and water, as well as no flammable, corrosive liquids or gases. The vibration or shock of the electric control cabinet is ≤0.5G, and the installation distance is ≥500 mm from the wall.

Installation places should be far away from large electrical noise sources (TIG welding devices, etc.).

The installation flatness of the robot base is less than 0.5mm.

3. Industrial Robot Training Content

1) Industrial robot installation and Parameter setting

2) Practical industrial robot training in operation mode and manual speed

3) Industrial robot programming training

4) Backup and recovery of industrial robot programming

5) Initial power on and IO configuration of industrial robot

6) Practical industrial robot training coordinate system calibration

7) Setting of the safe working area for industrial robot

8) Fault diagnosis and maintenance of industrial robot

9) Practical training in reading electrical drawings

10) Pneumatic circuit connecting pipe and electrical wiring

11) Application of detection switch

12) Application of various sensors

13) Application of pneumatic components

14) Installation and application of PLC

15) Installation and application of touchscreen

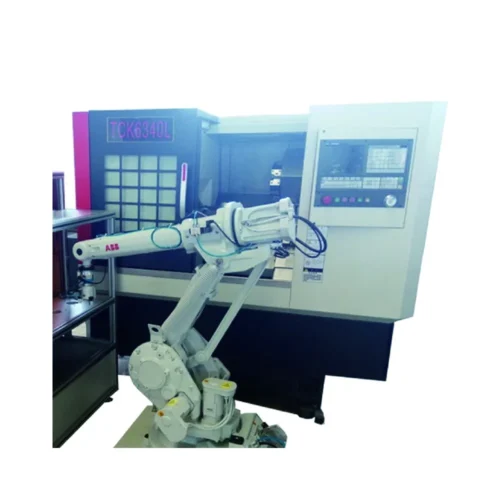

16) Communication between robot and PLC, HMI, Servo system

17) Application of quick change tools for industrial robots

18) Handling and palletizing tasks of industrial robots

19) Assembly task of industrial robot digital keyboard

20) Industrial robot gift packaging tasks

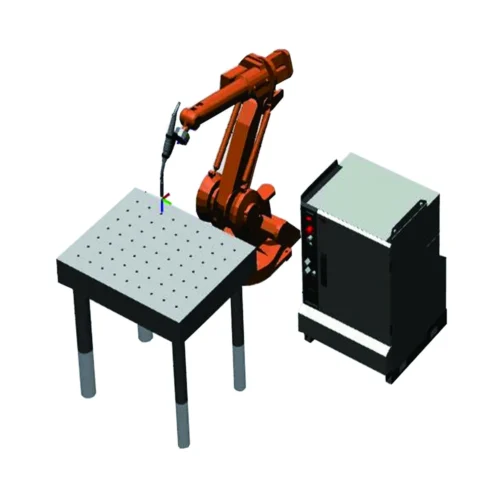

21) Industrial robot simulation welding task

22) Multi-variety material transfer and stacking tasks

23) Industrial robot trajectory drawing task

24) Curved surface task of industrial robot

25) Robot simulation software training

26) Common fault analysis and precision detection method of industrial robot

27) Industrial robot servo system commissioning

Reviews

There are no reviews yet.