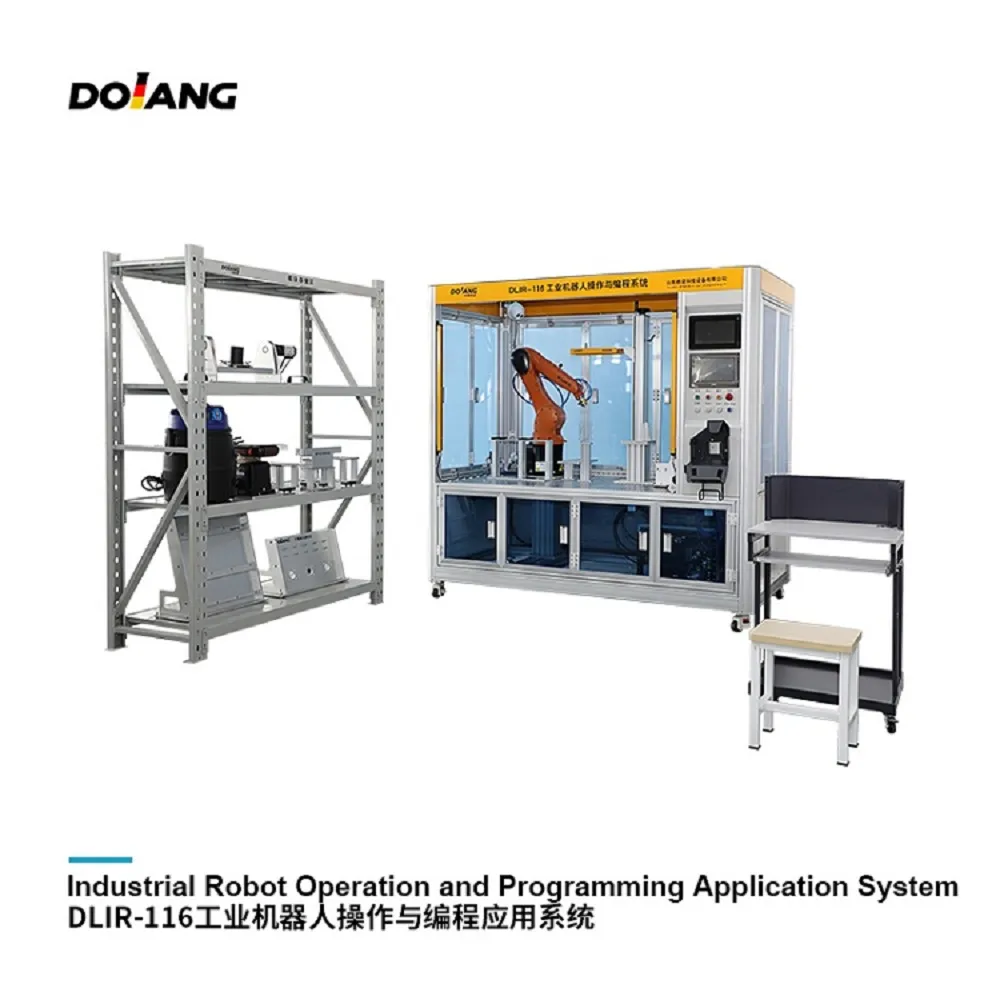

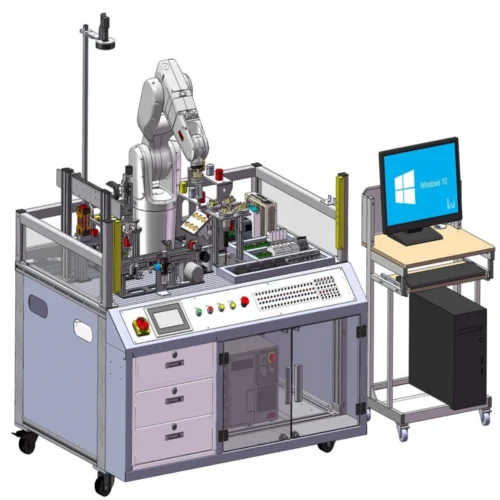

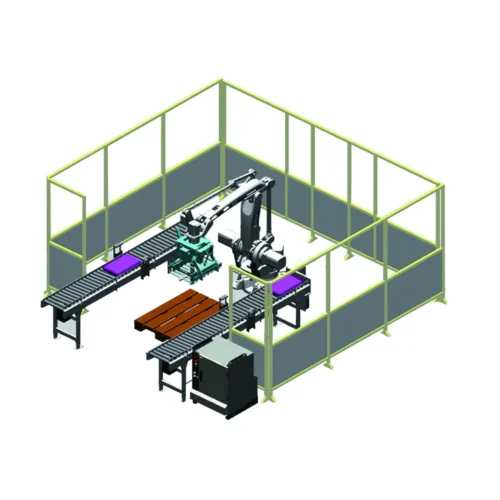

DLIR-116 Robotics Operating And Programming Training System

1. Overview

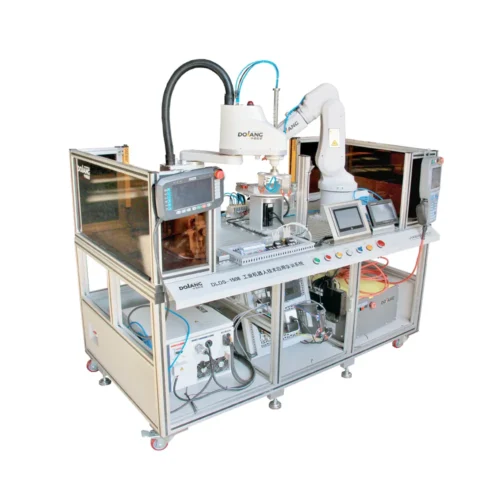

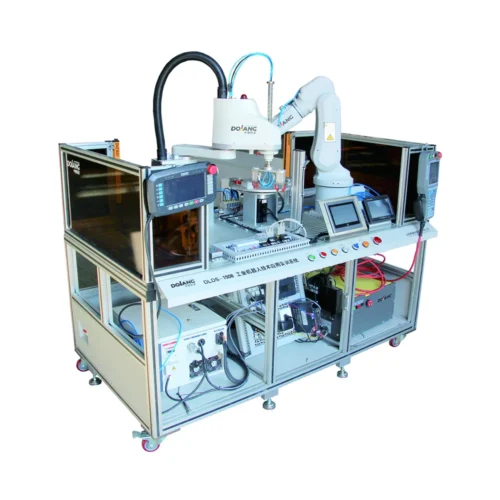

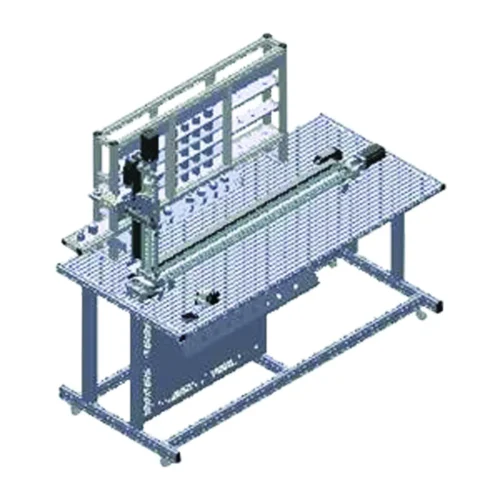

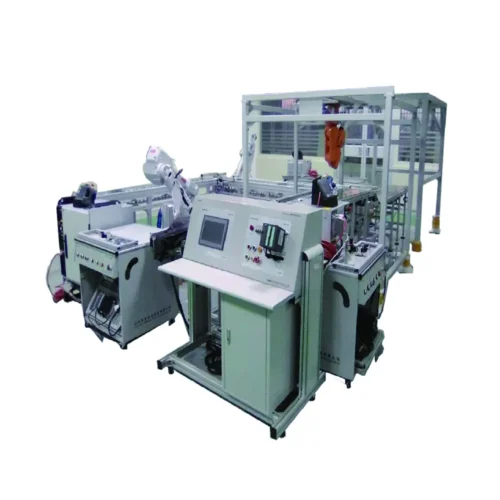

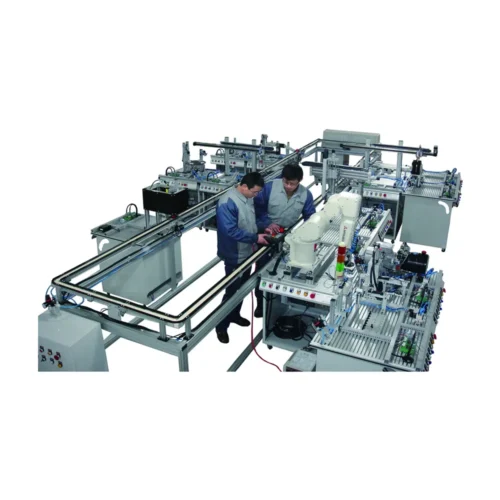

The DLIR-116 robotics training equipment for industrial robot system operation and maintenance personnel is designed according to the national vocational skill standard. The robot operating system adopts a modular structure, which can select different combinations of training modules on a unified platform.

The robotic operating system can meet the knowledge and skill requirements of intermediate workers, senior workers and technicians, and senior technicians.

2. Technical Parameters

DLIR-116 robot operating system’s upper part consists of an aluminum frame, transparent acrylic protective door, safety grating, and three-color indicator light, which can ensure safe operation. And the Lower part of the basic platform of the industrial robot adopts a sheet metal structure, which places the robot controller, etc.

The front right side of the basic platform of the industrial robot includes a control panel, HMI module, industrial display screen, etc., which is convenient for on-site operation and monitoring. And the control panel buttons include start, stop, reset, emergency stop, manual/automatic, and function buttons.

The bottom of the industrial robot’s basic platform is equipped with load-bearing casters with brakes, which are easy to move and adjust the platform’s position.

3. Robotics Training Content

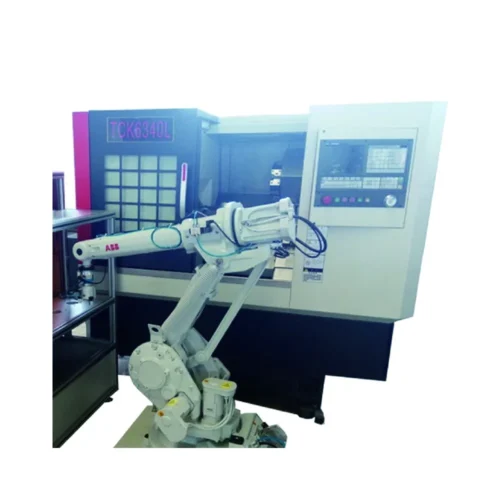

1) Installation and Parameter setting of industrial robots

2) Practical training in operation mode and manual speed of the industrial robot

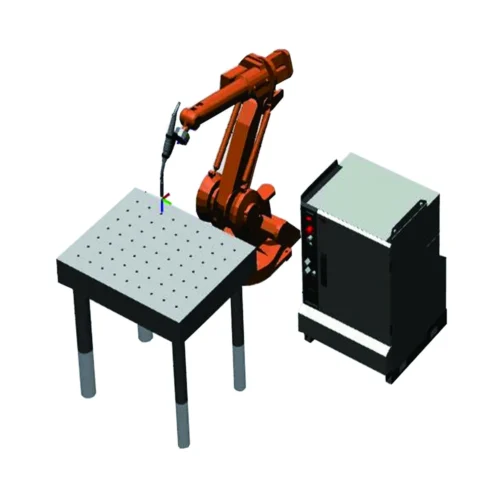

3) Industrial robot programming training

4) Backup and recovery of industrial robot programming

5) Initial power on and IO configuration of industrial robot

6) Practical training in industrial robot coordinate system calibration

7) Setting of the safe working area for industrial robot

8) Fault diagnosis and maintenance of industrial robot

9) Practical training in reading electrical drawings

10) Pneumatic circuit connecting and electrical wiring

Reviews

There are no reviews yet.