1. Overview

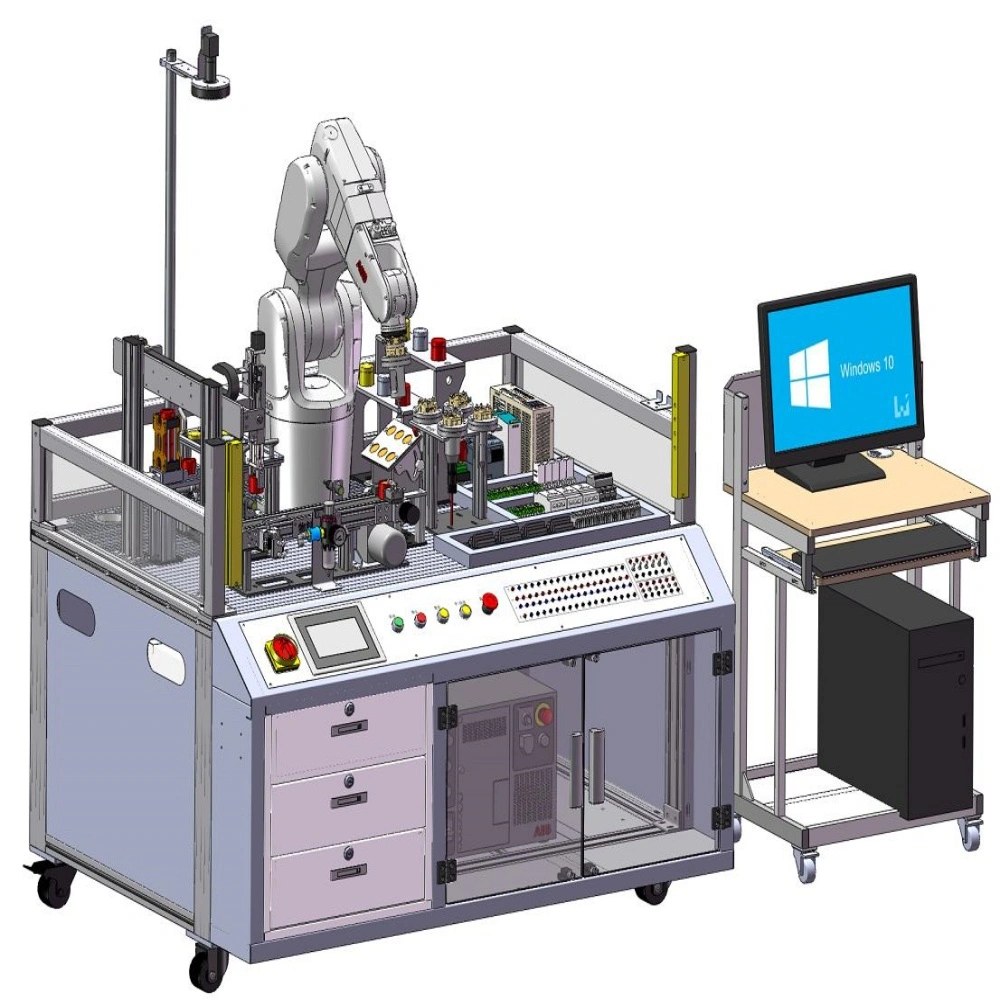

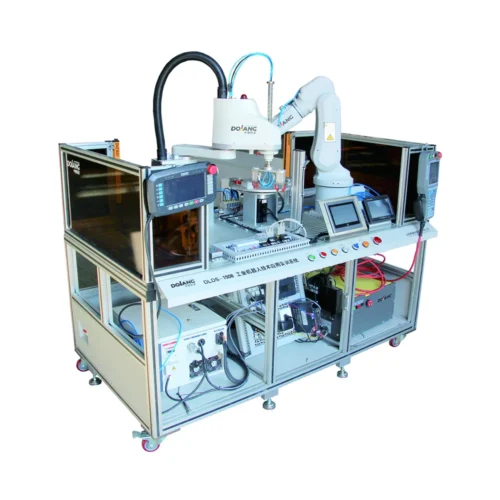

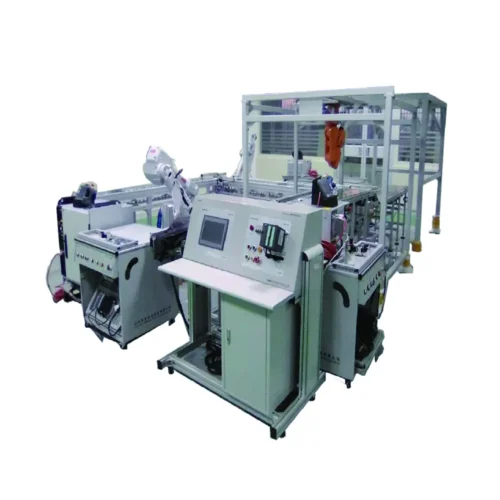

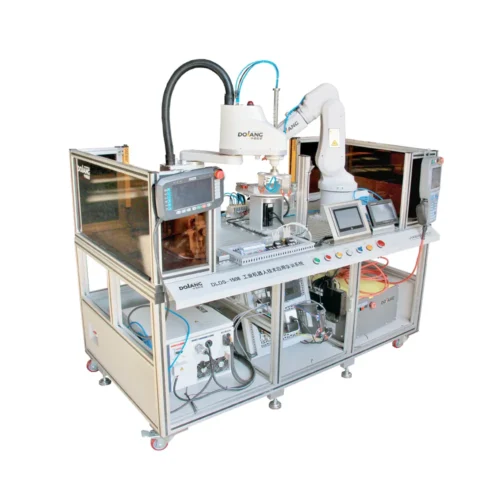

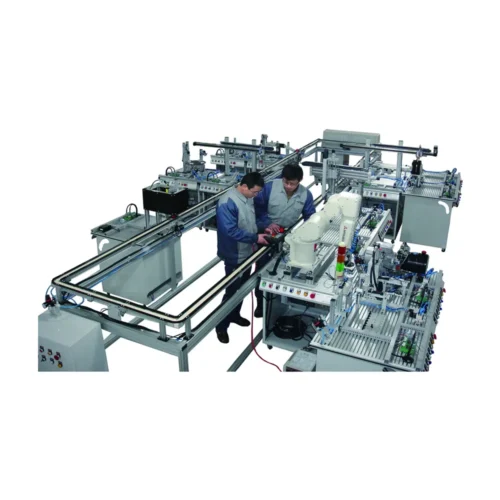

The platform can carry out skills training and assessment close to industrial field applications such as coordinate calibration of industrial robots, trajectory programming and operation, robot following, handling, palletizing, packaging, sorting, gluing, industrial visual inspection, etc. It can also be used for offline robot programming and Assessment of digital technologies such as simulation.

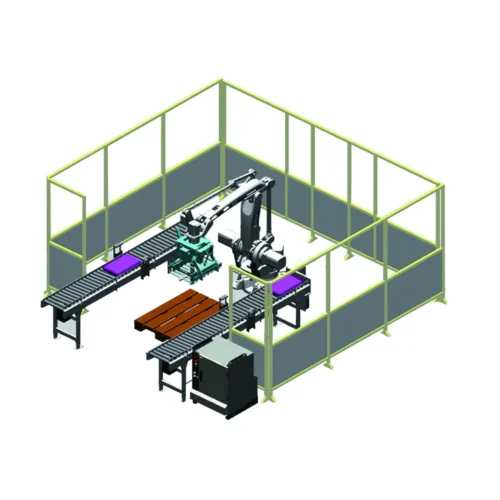

Process: feeding → manipulator grabs materials → conveyor belt transportation → placing commemorative coins → robot follows → stamping → storage

2. Technical parameters

2.1 Temperature: +5 to +45°; Environmental humidity: ≤85% (25°C).

2.2 System area: length × width × height ≈ 2.4m × 2m × 1.7m (width can be adjusted according to site conditions)

2.3 Equipment size: length × width × height = 1.5m × 1.1m × 1.17m

2.4 Machine power: about 2.5KVA.

2.5 Altitude: ≤4000m.

2.6 Input power supply: AC220V±10%.

Output power supply: DC24V.

2.7 Environment: Vibration ≤ 0.5G, no dust, corrosive gas, flammable gas, oil mist, water vapor, dripping water or salt, etc.

2.8 Reliable grounding of the system: grounding impedance <4 ohms.

2.9 Working air pressure: 0.6MPa.

2.10 Cooling method: natural cooling.

3. Training items

Section 1, Robot Training

1)Installation of industrial robots

2) Installation of industrial robot teaching pendant

3) Installation of industrial robot end tools

4) Setting of industrial robot parameters

5) Practical training on industrial robot operating modes and manual speeds

6) View common information on industrial robots

7) Introduction to industrial robot programming instructions

8) Backup and recovery of industrial robot programs

9) Practical training on calibration of industrial robot coordinate system

10) Industrial robot fault diagnosis and maintenance

Section 2, Electrical application training

11) Practical training on reading electrical drawings

12) Pneumatic circuit takeover and electrical connections

13) Application of detection switch

14) Application of various sensors

15) Application of pneumatic components

16) Installation and application of PLC

17) Installation and application of touch screen

Section 3, Equipment Communication Application Training

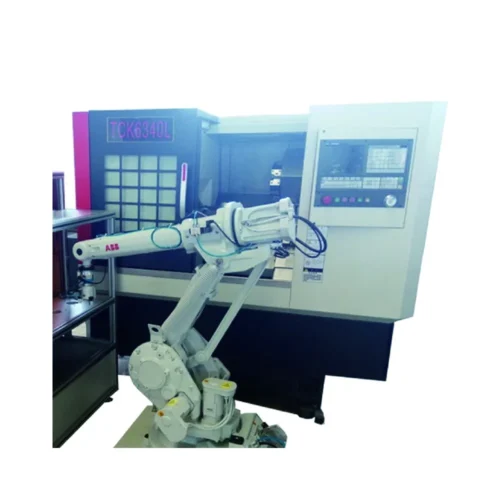

18)Robot and PLC communication

19) Touch screen and PLC communication

Section 4: Equipment comprehensive task training

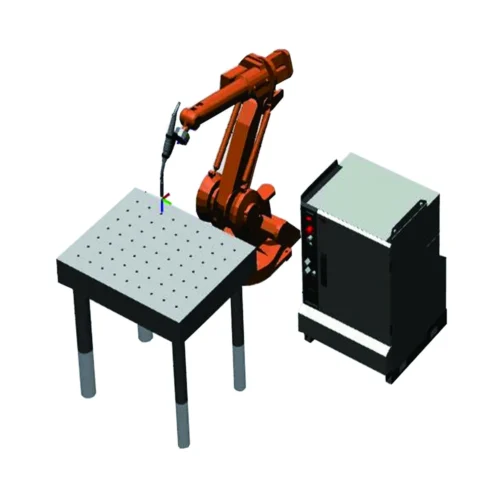

20) Industrial robot plane trajectory work tasks

21) Industrial robot curved surface work tasks

22) Practical training on industrial robots and visual communication

23) Application of industrial robot quick-change tools

24) Industrial robot handling and palletizing tasks

25)Visual sorting work tasks

26) Commemorative coin packaging tasks

27) Robot following task

28) Robot disassembly and assembly training using robot simulation software

29) Robot offline simulation training

Reviews

There are no reviews yet.