1. Overview

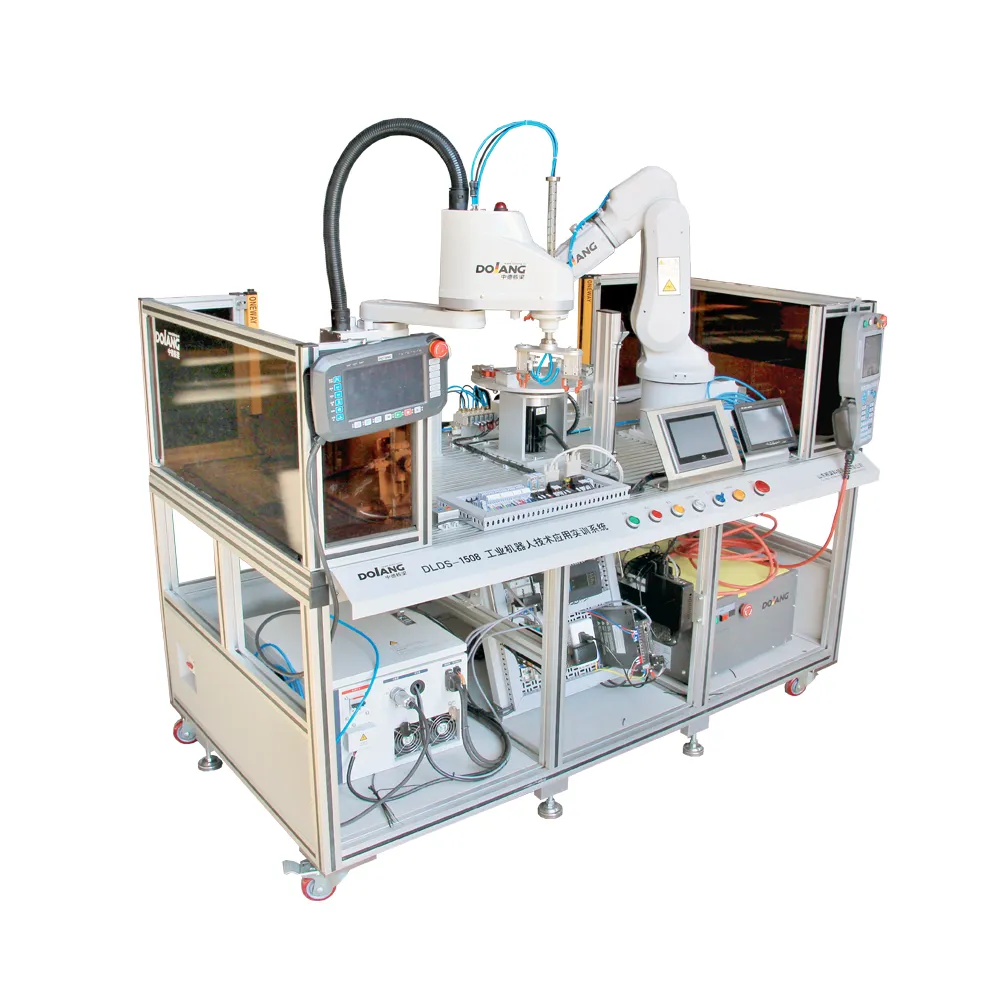

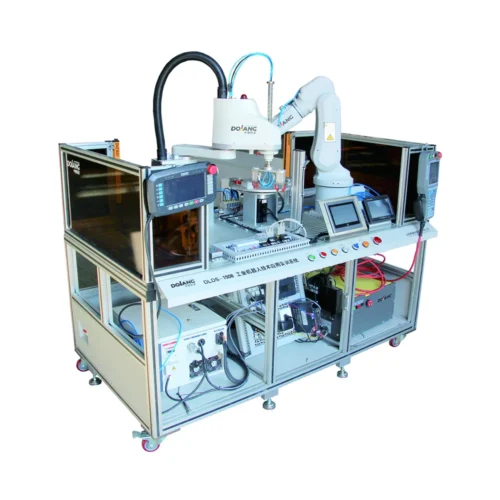

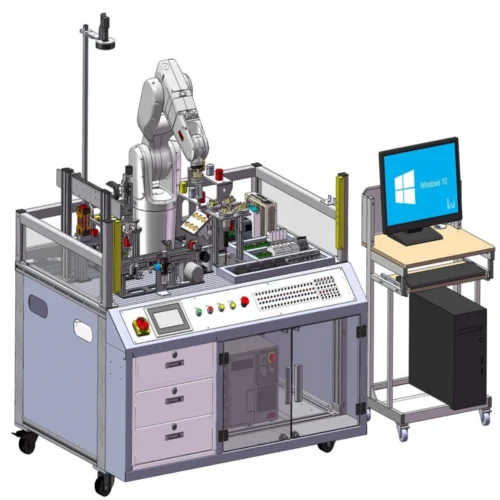

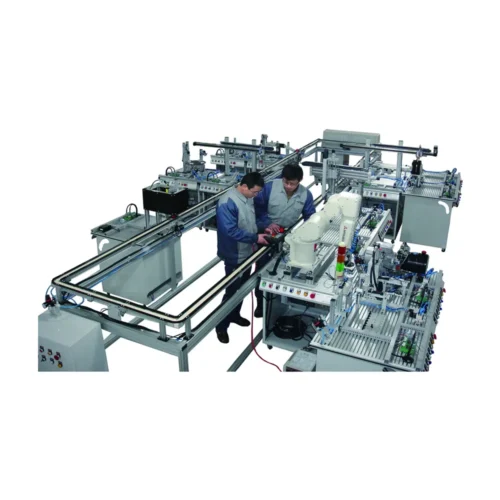

DLDS-1508 industrial robot training system consists of a workbench, spare parts store module, four-axis Berger Lahr mechanical handling module, ring assembly inspection mechanism module, ABB six joint industrial robot assembly sorting module, visual detection module, and finished product storehouse module.

The main task of the device is based on MES management software, and in order demand, the Berger Lahr robot grabs the corresponding to red or yellow, blue button cap and other button assembly parts from the spare parts store. And the assembly part is placed in a fixed position of the ring assembly detecting mechanism. The assembly structure detection is rotated 180 degrees, and reaches the assembly inspection station of the robot with six degrees of freedom. robot with six degrees of freedom carrying on the button assembly, after the completion of the assembly, the power supply mechanism sends electricity to the button. The robot presses the button, then through vision cameras to detect and judge the button’s color and quality, the six degrees of freedom robot according to the data of the vision camera for classification. Thereby it is carried in the finished product store.

2. Functional features

PLC: Siemens smart series or others’ brand PLC you need.

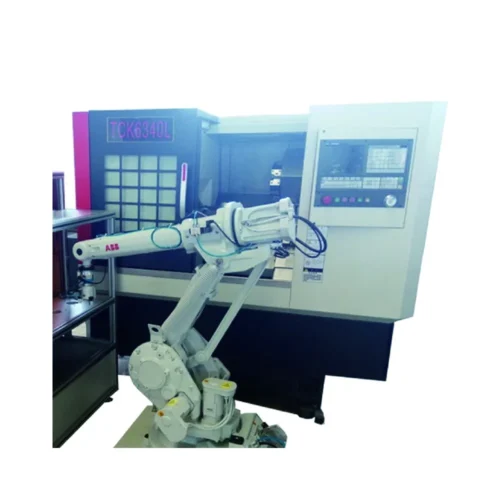

7) ABB six-joint robot:

(1) Robot model: IRB120-3/0.58.

(2) Maximum weight capacity: 3KG.

(3) Action semidiameter: 0.58m.

(4) Repeated positioning accuracy: 0.01mm.

Robot brands can select by customer needs, such as China-made industry robots, and Kuka robots….

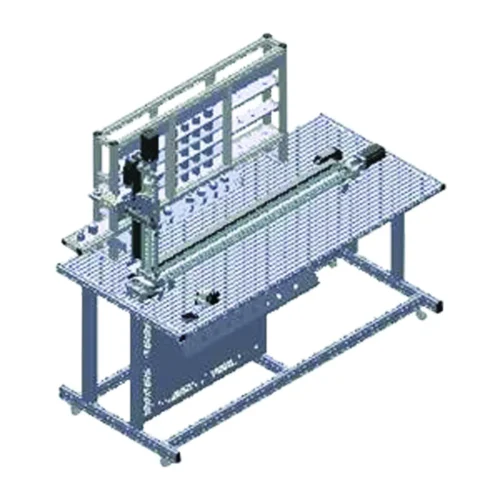

- Berger lahr manipulator

(1) X-axis stroke: 500mm;

(2) Y-axis stroke: 500mm;

(3) Z-axis stroke: 150mm;

(4) Rotation angle of rotating shaft: 180°.

3. Practical training that can be completed

1. Feeding unit of mechanical structure assembly and debugging training

2. Bergerlahr manipulator trajectory planning offline

3. Ring assembly inspection unit mechanical structure assembly and debugging practice training

4. Ring assembly detection unit PLC programming

5. Visual inspection module mechanical structure assembly and debugging practice

6. Visual inspection module electrical debugging

7. Understanding and application of the robot

8. Assembly unit industrial robot installation

9. Assembly unit finished product storage’s assembly and installation commissioning

10. Robot’s position control and command language training

11. Robot and PLC communication training

12. Robot peripheral equipment communication setup training

13. Robot trajectory planning training

14. Detection switch’s application

15. Variety of sensor’s applications

16. Pneumatic component’s application

17. Application of PLC

18. PLC Ethernet communication function

19. Pneumatic circuit connection and electrical connection

20. Mechanical parts and pneumatic parts assembly and disassembly

Reviews

There are no reviews yet.