1. Overview

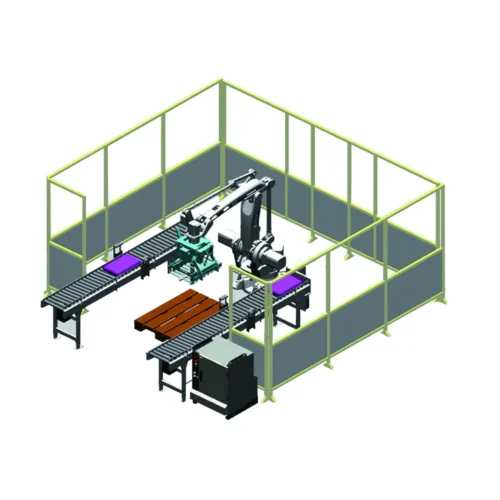

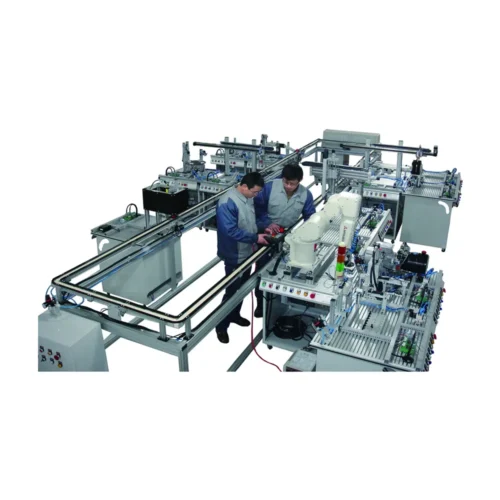

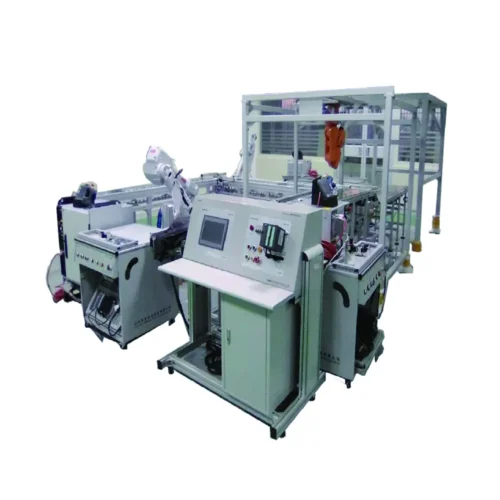

DLIM-WL08 logistics management system, through the network interconnection, data intercommunication and system interoperability of industrial resources, realizes the flexible ways of warehouse customization, material order storage, selection of storage, upper storage and lower storage, and material storage. The process is carried out according to the selected method, and the reasonable optimization of the logistics system enables the efficient use of resources, thereby building a high-efficiency, high-precision, and high-standard logistics management system.

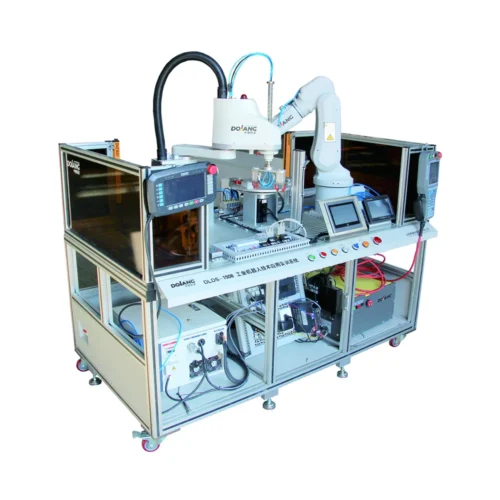

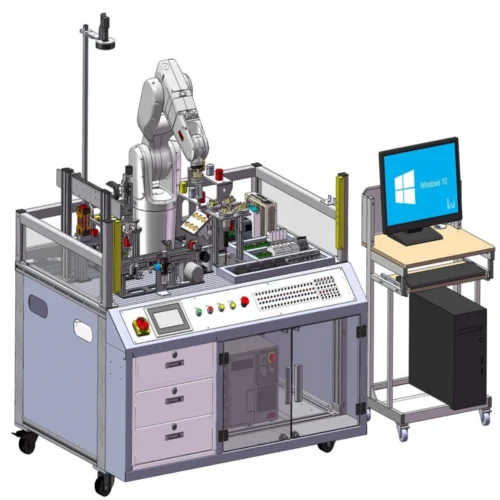

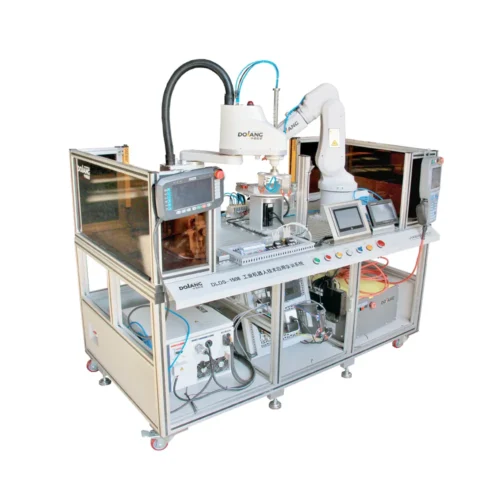

DLIM-WL08 logistics management system, the hardware is mainly composed of six-axis industrial robot handling unit, digital storage unit, manipulator transfer unit, code scanning gun scanning unit, and the software is mainly composed of PLC programming software and WINCC system software.

2. Hardware introduction

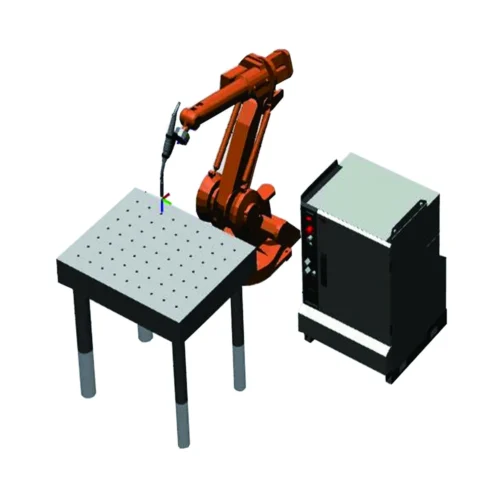

2.1 The six-axis industrial robot module is mainly composed of six-joint industrial robot, teaching device and bracket, control cabinet, pneumatic gripper, etc. The robot adopts KUKA KR4 R600 type.

KUKA robot panel HMI interface status bar

The status bar shows the status of the industrial robot-specific central settings. In most cases a touch will open a window in which the settings can be changed.

2.2 Storage module

It is composed of industrial aluminum profile bracket, storage platform, buffer platform, etc., and is used to store material blocks. An electronic label is installed on the front, which is used to display the number of storage bins.

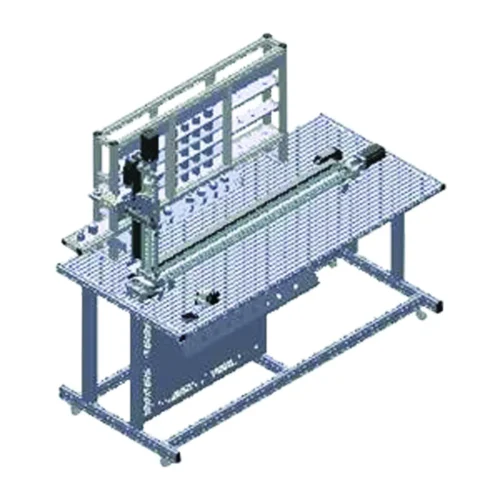

2.3 Manipulator transfer unit

The manipulator transfer unit is mainly composed of screw, DC motor, pneumatic gripper, magnetic sensor, micro switch, etc. It is used to pick up materials from the transfer table for storage and pick up materials from the warehouse for delivery.

3. Experiment contents

Training 1. Understanding of motion control

Training 2. DC motor training application

Training 3 Six-axis industrial robot grasping and handling training application

Training 4. NODE – RED control motor control

Training 5. Warehouse and manipulator cooperation training application

Training 6 WINCC interface to create training applications

Training 7. Electronic label and node-red training application

Training 8. Application of bar code scanning gun and material selection in WINCC cache area

Training 9. Application of code scanning gun and WINCC storage material outbound training

Training 10 WINCC control six-axis industrial robot training application

Reviews

There are no reviews yet.