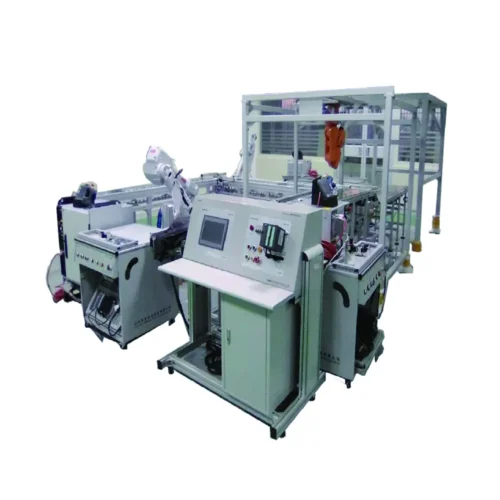

DLRB-501D Robotics Training Equipment Description

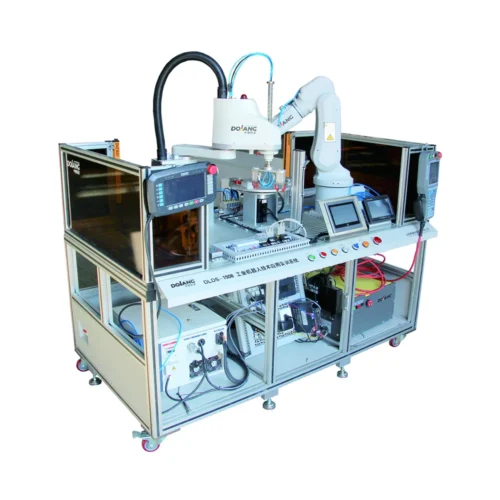

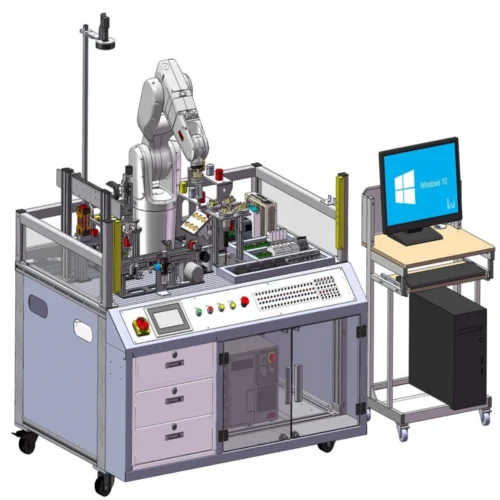

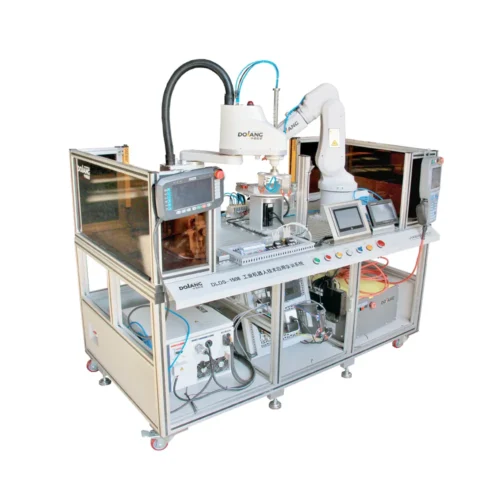

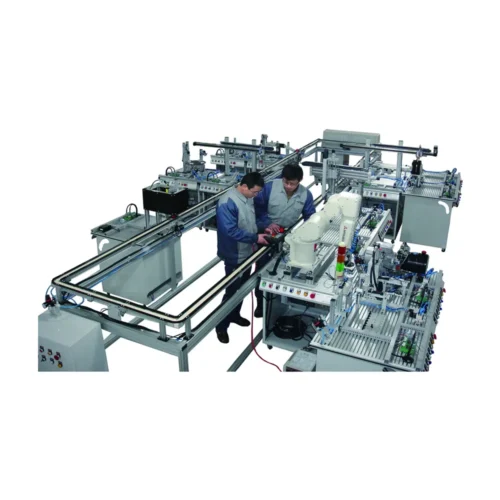

The robotics training system demonstrates candy’s sorting and packaging process, including raw materials, visual inspection, sorting, assembly and handling, and palletizing storage. It can correspond to the actual industry 3.0 product processes: raw materials, machines, factories, transport, and sales, and provide strong foundation support for the promotion of industry 4.0. This robotics training equipment covers many technologies, such as electrical control, industrial robot, programmable controller, and information technology. It also includes industrial processes such as logistics, packaging, handling, and sorting.

Robotics training equipment is widely used in vocational schools and universities for Technical Training Aids.

Technical Parameters

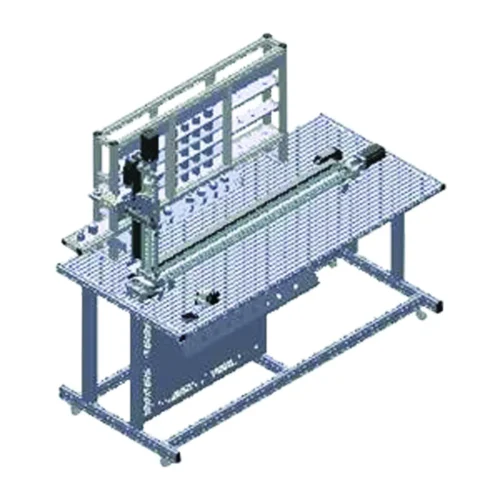

DLRB-501D Industrial Robot Candy Packaging and Handling System module includes five working units (workstations): handling / palletizing station, loading station, sorting station, packing station, and U-type transmission station.

Robotics Training Content

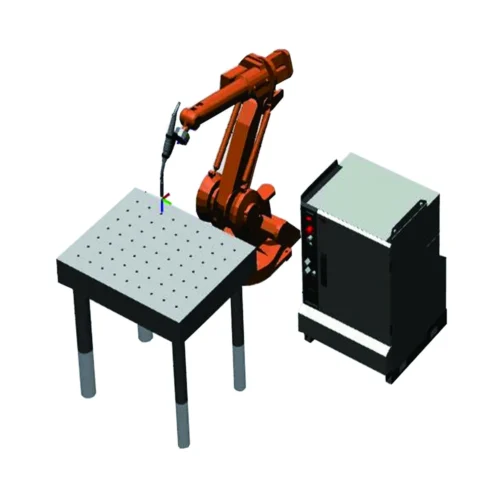

1. Installation and wiring of 6 – axis Industrial Robot

2. 6- axis Industrial Robot Parameter setting.

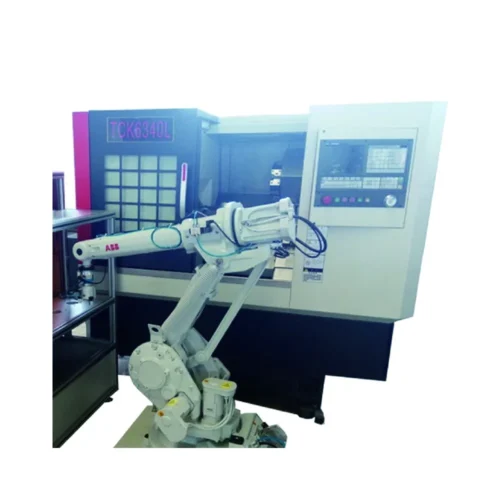

3. IO Communication between 6-axis industrial robot and PLC.

4. Programming and communication of 6 Axis Industrial Robots.

5. Installation wiring of robot and controller.

6. Handling unit installation wiring and commission

7. Unpacking, installation, wiring, and commissioning of the loading unit

8. Visual inspection and sorting unit installation wiring and debugging

9. Installation of wiring and debugging of the transport unit.

10. vision system parameter setting and debugging&communication,

11. Siemens System Industrial Ethernet application programming.

12. Production line integrated programming and debugging.

Reviews

There are no reviews yet.